JEC WORLD AERO PLANET - Showcasing composites innovations.

NEUE MATERIALIEN BAYREUTH GmbH

Partners

Airbus, BMW Group, Werkzeugbau Siegfried Hofmann, BASF SE, SGL - 6 D25

Neenah's Part

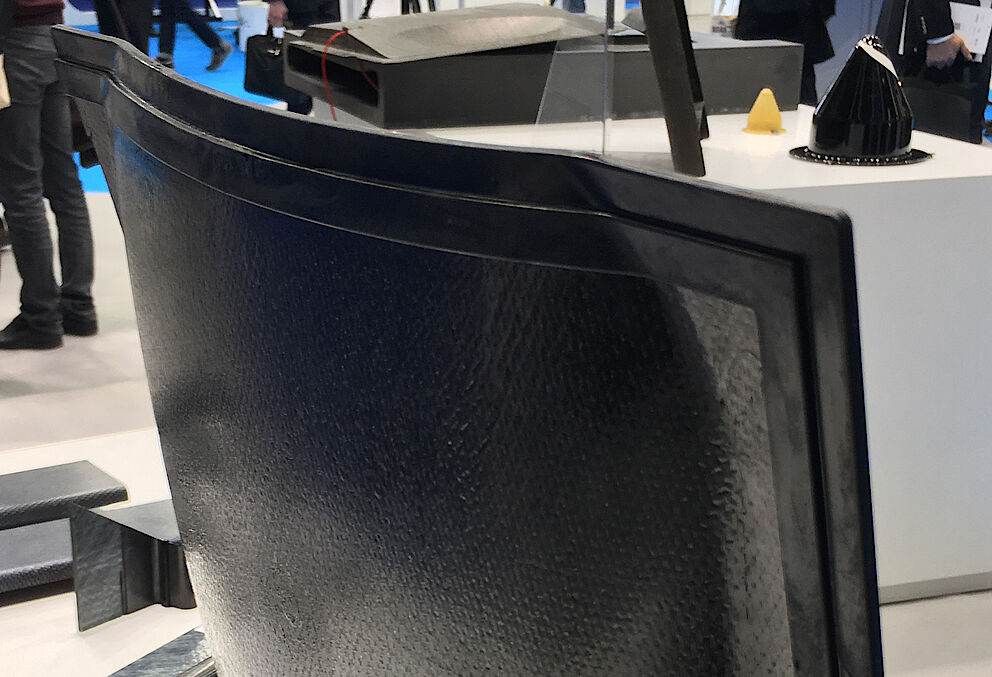

MAI-Sandwich Demonstrator

Main application

Aircraft and Automotive lightweight sandwich structures

Genesis of Neenah product. Why and for whom?

For the team it was obvious that the breakthrough of the CFRP technology into a large scale production has to be prepared. Aim was a cost effective complex 2.5 D thermoplastic sandwich, with a very short cycle time of less than 5 min (aeronautic/AIRBUS) and less than 2.5 min (automotive/BMW)

Benefits for the final customers

Thermoplastic composites presecced by combined compression and injection molding enable the final customer to use a lightweight sandwich part, that can be produced in a one-shot process. Short cycle times and high degree of function integration allow ecenomic mass production.

The product: materials and processes

The part in manufactured in one machine and one mold. Endless fiber reinforced thermoplastic face sheets are thermoformed and joined with a foam-or fold.or rib-core without adhesive layer. Injection molding is used to add function integration like ribs and accurate edges: no rework is needed. Materials like PP/PA were used for automotive applications and PES/PEI/PEEK for aeronautic applications.