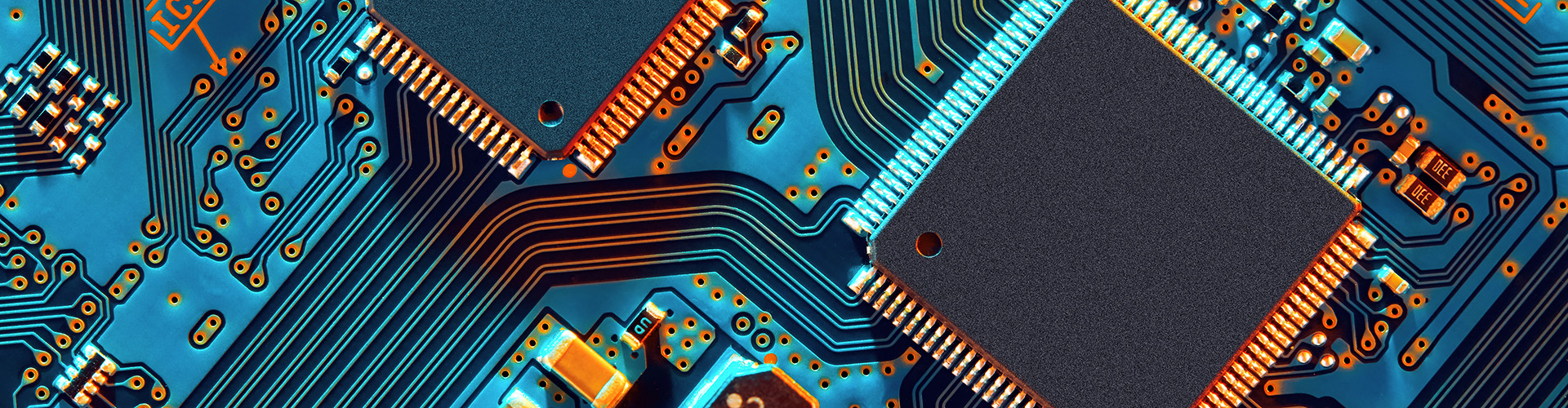

ELEVATE YOUR SEMICONDUCTOR AND ELECTRONICS WITH ULTRA-PURE RESIN FILMS

MEDIA SUPPORT

Our GESSNER Delnet™ Apertured Films provide ultra-pure resin options that are designed to minimize contamination in critical applications such as semiconductors. Our resin options come in multiple options based on temperature and chemical compatibility requirements, offering a tailor-made design that ensures no contamination of fluids.

We provide high-temperature options that are specifically tailored to meet your needs and are designed to provide maximum performance and reliability even in the toughest applications, ensuring that you get the best results every time. Our films are engineered to provide the highest level of performance and reliability in critical applications, offering a unique and tailored solution.

Why Use Apertured Films For Semiconductors?

The use of apertured film as a support structure of material can have a significant impact on the production of semiconductors. This type of support media provides a stable and secure structure for the semiconductor material during the manufacturing process.

- The apertured film's structure allows for excellent control over the semiconductor's thickness, which is crucial for ensuring its performance. By providing uniform support across the entire surface, it helps maintain the consistency of the semiconductor layers.

- The apertures in the film allow for efficient gas and heat exchange during the production process. This can enhance the quality of the semiconductors by ensuring uniform heating and cooling, which is vital for the formation of the semiconductor's crystalline structure.

- The use of apertured films can also lead to cost savings in the manufacturing process. They can be produced and applied more efficiently than other types of support media, reducing the overall production time and cost.

In conclusion, the use of apertured films as a support media can improve the quality, efficiency, and cost-effectiveness of semiconductor production.