FILTER MEDIA FOR OIL FILTERS

We offer a wide variety of grades to meet individual process and filter requirements: 100% cellulose, combinations made of cellulose, glass, and synthetic fibers or layered media. GESSNER is able to tailor the media onto your special requirements, from a highly efficient filter media, also as corrugated grades available, which increase filter lifetime to its optimum.

Efficientand Sustainable: FSC® Certified Oil Filter Media by GESSNER

GESSNER's filter media solution made of 100% cellulose media are saturated with phenolic resins, making them more durable and long-lasting than other standard filter media solutions. Highly developed media with our gradient structure improve depth filtration thanks to their media structure and composition.

As we know that every application has special requirements, we also offer our grades in corrugated form to meet a wide range of customer requirements. The corrugated media structure stabilizes the pleats, preventing them from collapsing and thus increasing the filter efficiency. With this option, we provide greater flexibility and choice, ensuring that our customers can find the ideal solution for their specific needs.

For those looking for a sustainable filter media, we offer FSC® certified grades of our cellulose filter paper, sourced from responsibly managed forests. With those media you can be sure that you are getting a high-quality filter media solution that is also sustainably sourced from responsibly managed forests, contributing to environmental, social, and economic benefits.

Synthetic and Glass Fibers Tech

GESSNER also offers filter solutions that combine a cellulose media with synthetic and/or glass fibers to achieve the best possible filtration performance. They are designed to achieve even higher efficiencies due to their media structure.

GESSNER's fully synthetic oil filter media is composed of wet-laid synthetic fibers, which can be reinforced with a Naltex™ netting for additional pleat support. This media structure ensures better processing and superior stability due to the media composition, which provides improved capacity and efficiency and allows for longer drain intervals. In addition, our fully synthetic oil filter media provides improved oil flow which not only results in increased filter efficiency but also ensures optimized component protection even under extreme conditions.

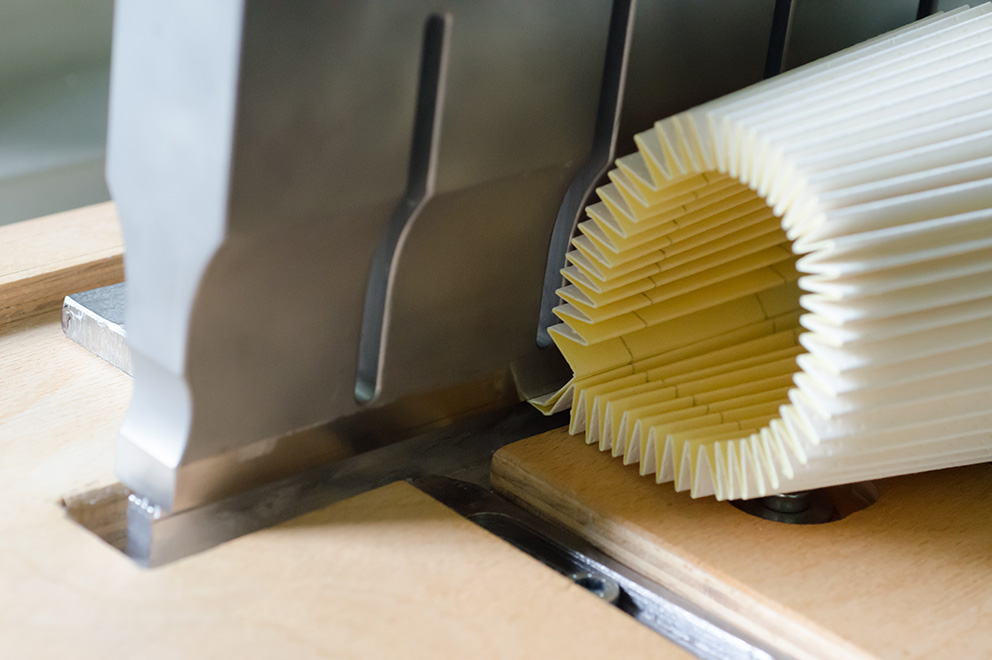

PLEAT SUPPORT FOR OIL FILTERS

Protective Pleat Support with Naltex™

Naltex™ netting is a pleat support material used in oil filter elements, helping to protect and extend their lifespan, especially when using synthetic filter medias. It provides structural support to the lengthwise folds of synthetic media, allowing for more pleats per inch while increasing air flow. This pleat support works by extending the filter's ability to capture more dirt and particles, leading to a more efficient filtration process. Naltex™ netting is specifically designed to be lightweight, yet strong and durable for the toughest of environments.