OUR CELLULOSE-WET-LAID TECHNOLOGY

OUR TECHNOLOGICAL ADVANTAGE

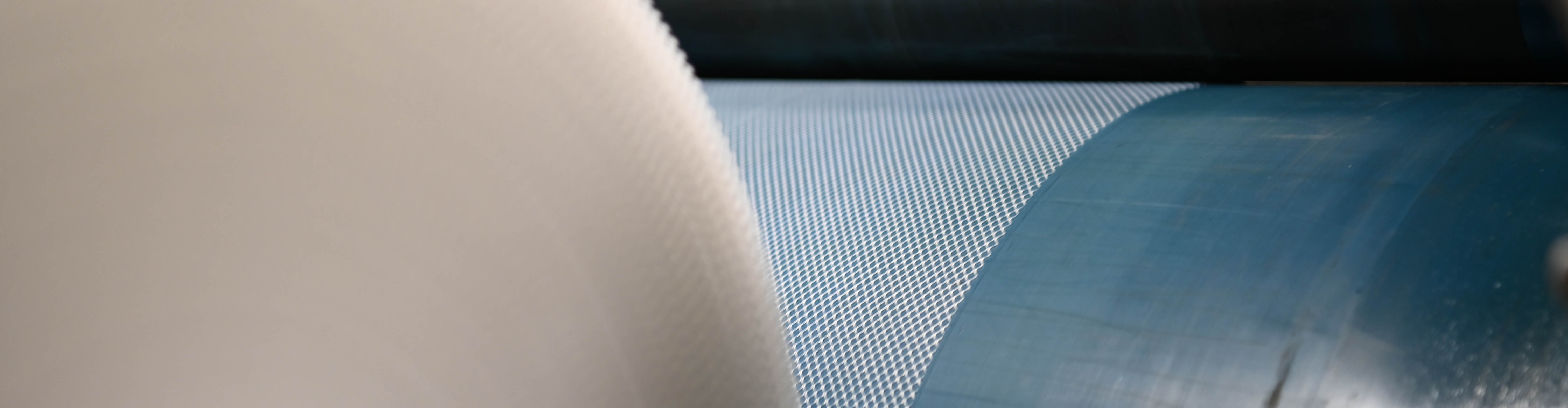

Our inclined and flat wire paper machines provide exceptional performance when it comes to producing technical special papers. With these machines, you can achieve weights of 18 – 250g/m² and air permeabilities of 1 – 2000 l/m²/s. This ensures that you have the perfect product for your needs every single time. Alongside selected cellulose fibres, we use synthetic, glass or carbon fibres to give further special properties, such as strength.

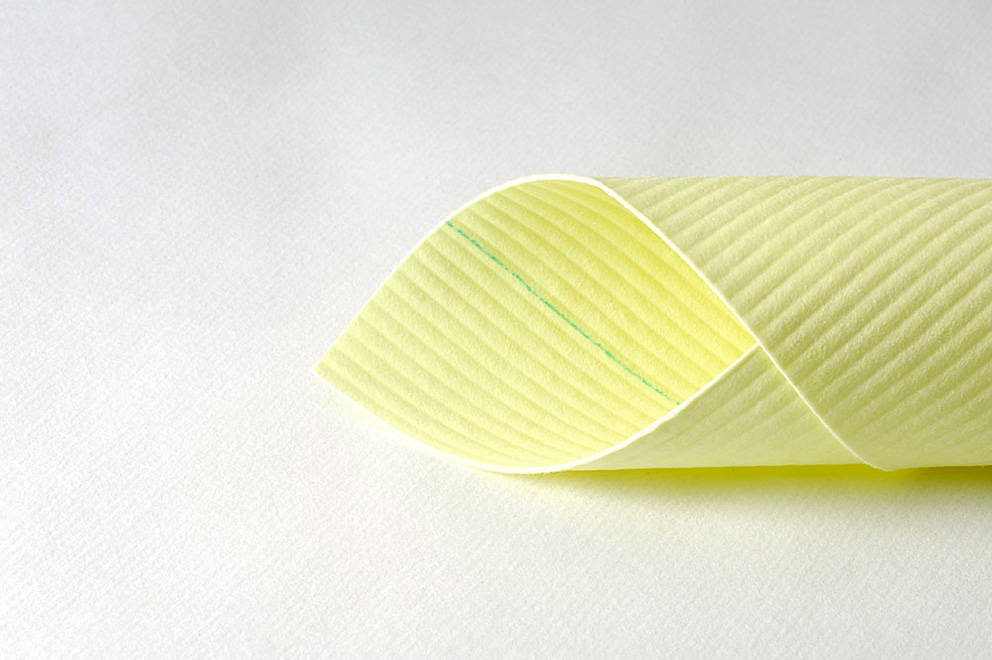

With creping technology, we can achieve different surface characteristics, from very fine to very rough crepe profiles, and with various stretch properties.

ADDITIONAL PROPERTIES THROUGH SATURATION

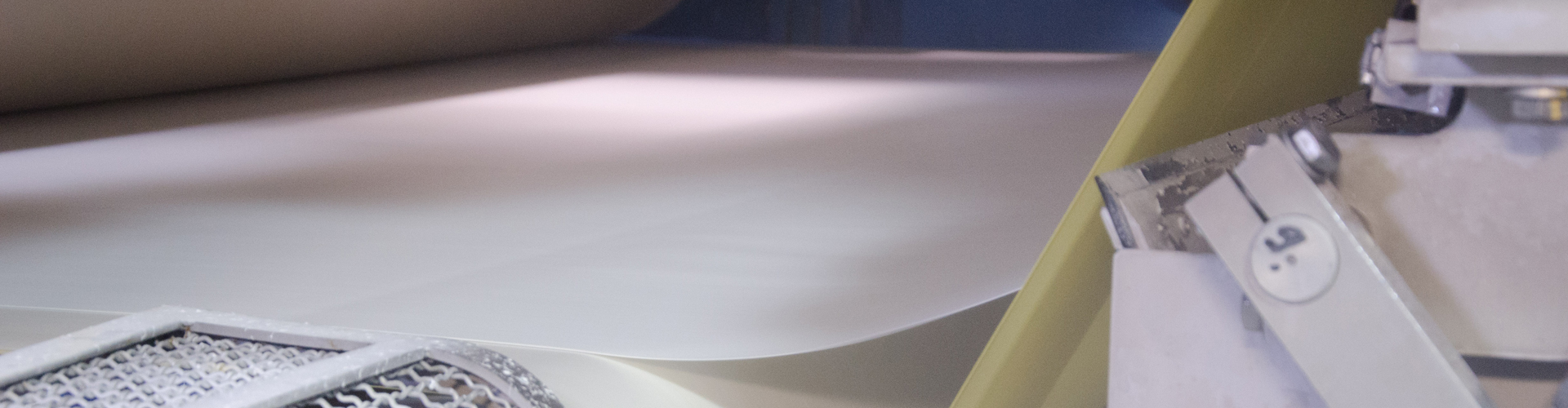

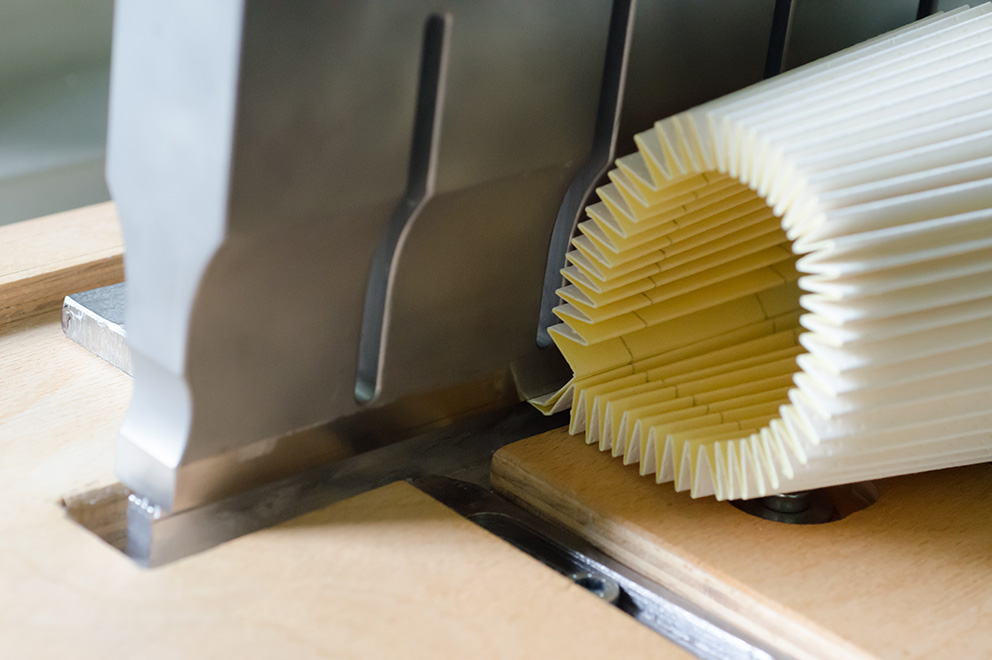

The saturation process is the key to our cellulose-wet-laid technology. This process allows us to create stronger, more durable nonwovens with improved properties. Our unique saturation process helps to create stronger, more durable nonwovens that can withstand higher temperatures and pressures. This helps to improve the performance of filtration applications, providing superior filtration efficiency, longer lasting filtration solutions, and many more characteristics.

Special additives, depending on need, can be added to give further functionality. For example, hydrophobic, hydrophilic or oleophobic properties, flame retardancy, various colors, UV stability, bactericides, fungicides, etc, can all be built-in. Using further coating devices, we can add still further functionalities. Our ability of an asymmetric saturation process provides many different functionalities of cellulose-based media. This technology ensures that the impregnation of our filter media can provide optimal filtration capabilities when used in a range of industrial settings, especially when it comes to customized and very special requirements.