Our StretchWrap's Triumphant Test Results Across Turnable, Automatic, and Hand Wrappers

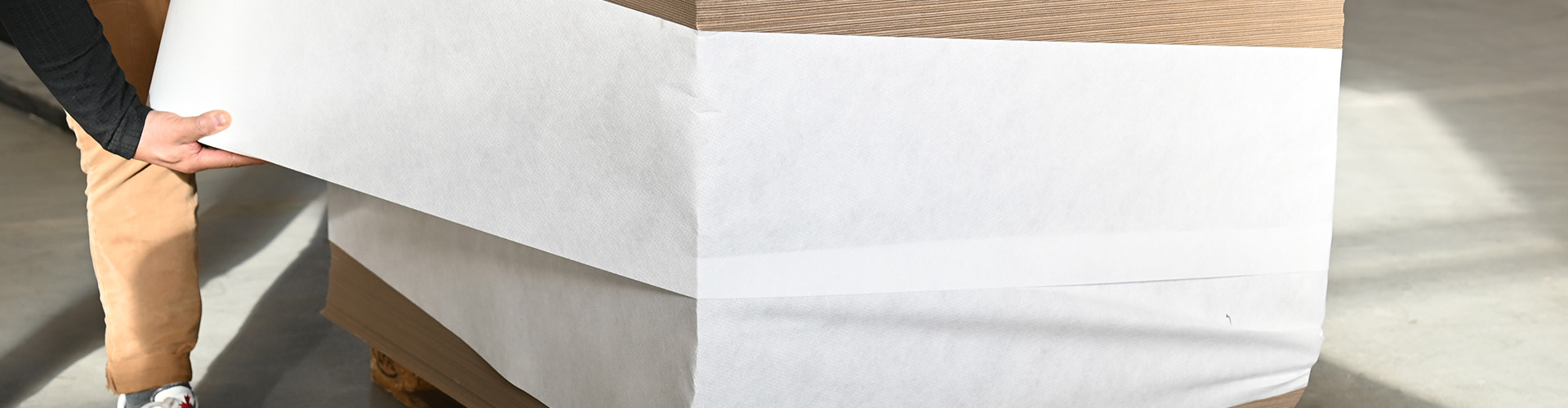

Our sustainable stretch wrap material has been put through rigorous application tests, and the results have been overwhelmingly successful. Our StretchWrap was test on 3 different wrappers:

- Turntable wrapper

- Automatic wrapper

- Hand wrapper

The broad range of applications collectively highlighted the material's high efficiency and flexibility across various wrapping applications, positioning itself as a powerful alternative to traditional stretch films. The tests demonstrated the material's ease of use, flexibility, adaptability, and resilience under different conditions.

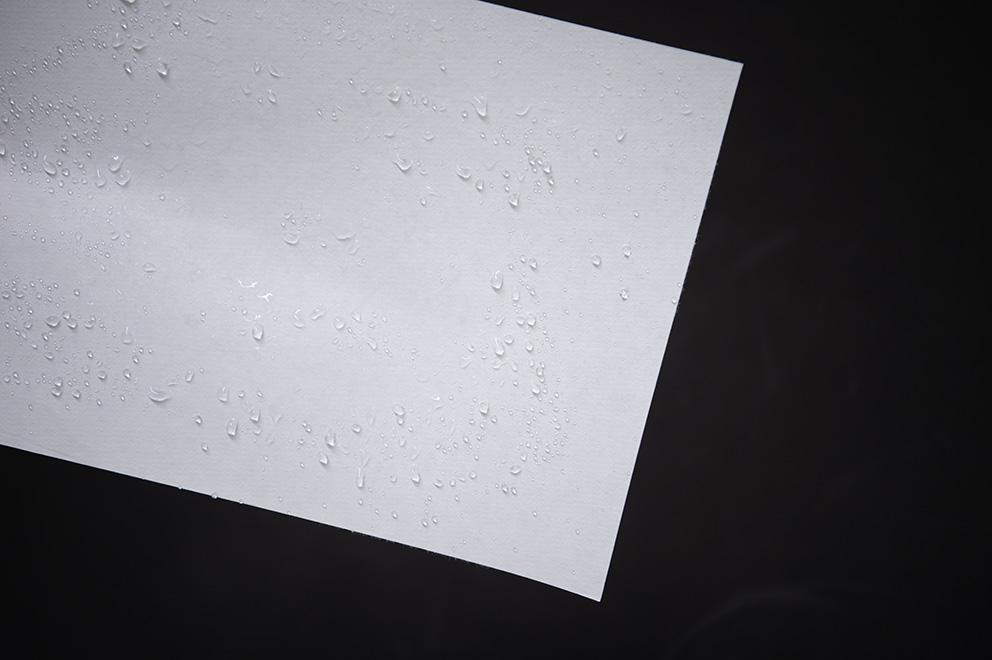

Since our paper has a higher fiber strength, less material is needed per pallet than a thinner plastic film with lower tear strength, of which more is needed to wrap a pallet for sufficient protection. The same weight of packaging material is produced - even though our material is slightly heavier than conventional stretch film, less of it is required due to its high tensile strength.

Our innovative StretchWrap paper has been designed so that it can be used on conventional turntable, automatic and hand wrappers. Depending on the thickness of the grade, there is a small adjustment that requires a fixation of the end, for which there are various solutions on the market that allow you to upgrade your wrapper with an adhesive tape application or a glue applicator.

These successful application runs signify a crucial step forward in our mission to replace traditional stretch films with sustainable packaging materials. With our stretch wrap material, we are offering more than just a product; we are delivering a promise of quality, efficiency, and sustainability.