REINFORCEMENT FOR YOUR AEROSPACE COMPOSITES

WITH OUR CRANEGLAS™ GLASS WET-LAID NONWOVEN MEDIA

MEDIA SUPPORT

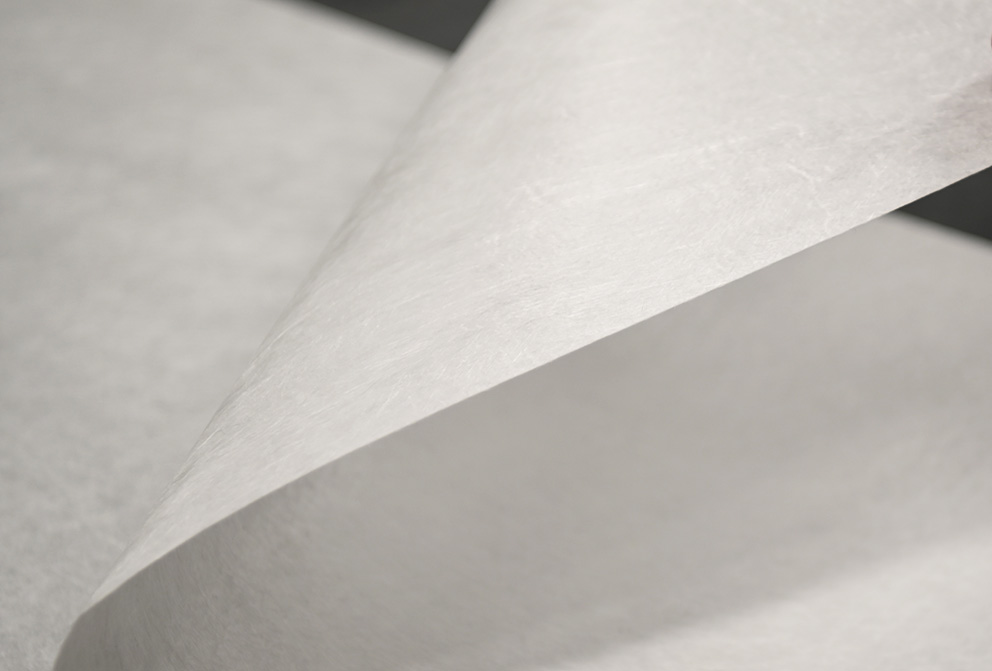

CRANEGLAS™ glass nonwoven media was developed to have high temperature resistance with a thermoplastic base, making it easy to mold. This media is designed to be used in aerospace composites, providing superior protection against heat and allowing for complex shaping of the composite materials. This media has been tested and certified, ensuring that it meets the highest standards of safety and performance.

The CRANEGLAS™ glass nonwoven media has superior flame, smoke (ASTM E662) & toxicity (BSS 7239) ratings compared to other media products. This makes it ideal for use in aerospace composites due to its ability to meet the highest standards of safety and performance. Additionally, this media has a low outgassing rate, meaning that it will not release any harmful toxins or substances into the air.

One of the key benefits of the CRANEGLAS™ glass nonwoven media is its lightweight design. This media is much lighter than other materials, making it much easier to transport and mold into complex shapes. This lightweight design also helps to reduce the overall weight of the composite materials, making them much more efficient and cost-effective.