ENGINEERED FOR EFFICIENCY: GESSNER'S FILTER MEDIA AND PLEAT SUPPORT, DESIGNED FOR TOMORROW'S ROADS

ENGINE AIR FILTER MEDIA

At GESSNER, we offer a broad range of engine air filter media designed to meet the rigorous demands of markets around the world. Our technology provides media that can withstand the toughest environments. Our paper-meltblown combinations are engineered for high-end applications. Our self-designed resin systems provide high stiffness in both dry and wet conditions. Our media are resistant against water and temperature, so the media can be quickly dried to avoid filter collapsing. Plus, our system prevents low dusting during further processing.

At GESSNER, we strive to provide solutions that are better for the environment. We have earned the FSC® certification which is available for our paper-made products. Plus, our curing and no-curing resins are perfect for environmentally conscious businesses.

With GESSNER, you can rest assured that you are receiving a high-quality product. We guarantee a reliable, long-lasting product that meets the highest standards of quality. Our goal is to provide our customers with a superior product.

Especially when it comes to flame retardancy, GESSNER offers outstanding features. Our filter media solutions for engine air are available as fast curing and non curing solutions and fulfill the water resistant test TL848 with both cure and non-cure resins and are obligatory in Europe for OEM/OES, based on the test method DIN 53438.

Our flame retardant paper provides the perfect balance of performance and safety, with no heavy metals or halogenated compounds and without any chemical compounds, which are classified according to the VDA-list. Our media have a good wet stiffness and evaporation performance.

Learn more about our latest developments:

- 100% Cellulose - double dust holding capacity at high face velocity

LEARN MORE High-Performance Air Filter Media for Heavy-Duty Applications

LEARN MORE

Improved dust holding capacity and flame retardancy combined with tailored processing advantages

LEARN MORE

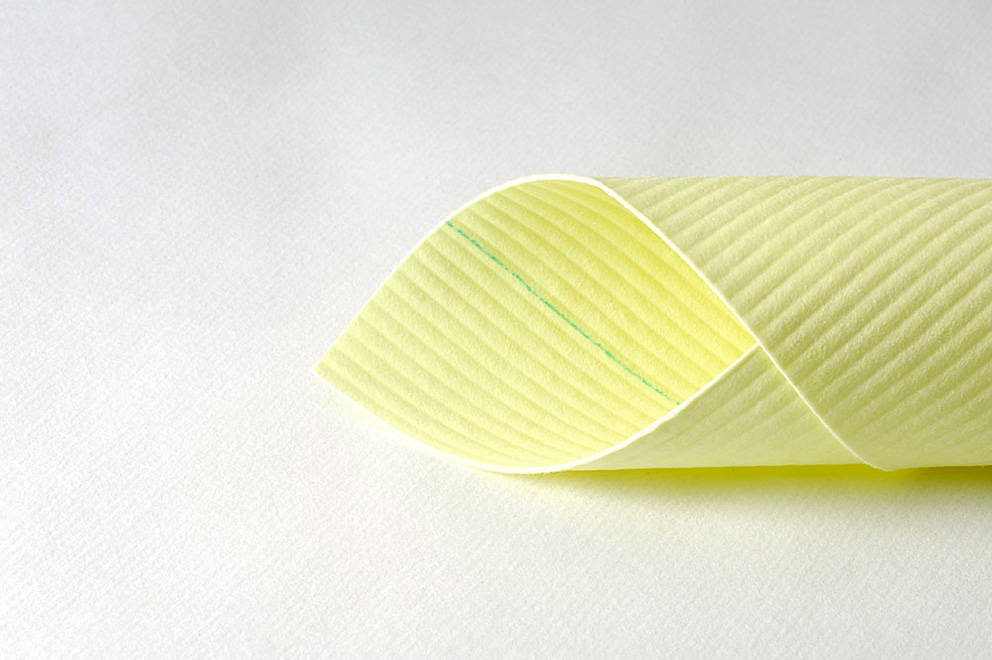

PLEAT SUPPORT FOR ENGINE AIR FILTERS

At GESSNER, we offer a range of Naltex™ pleat support nettings for engine air filters that provide superior performance and stability. Our self-designed resin systems create a rigid structure, allowing the media to withstand even the toughest environments. This ensures maximum efficiency, with no pleat collapse.