- Home

- Company Overview

- Applications

- Solutions

- Materials & Technologies

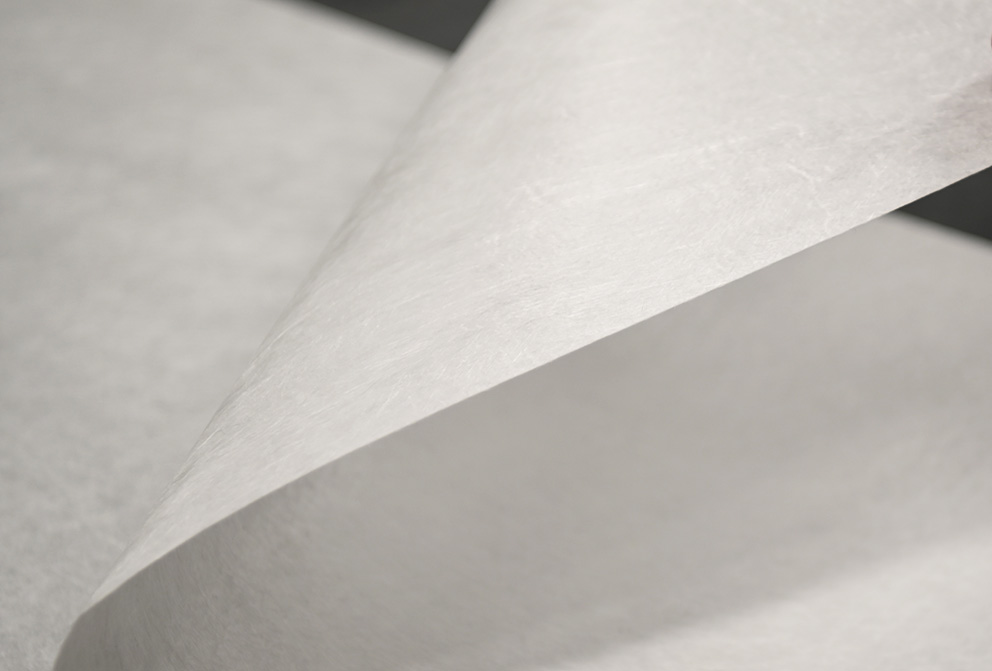

- Meltblown Nonwovens

- Electrostatic Nonwovens - Alphastar™

- Thermal Bonded Nonwovens - Delpore™

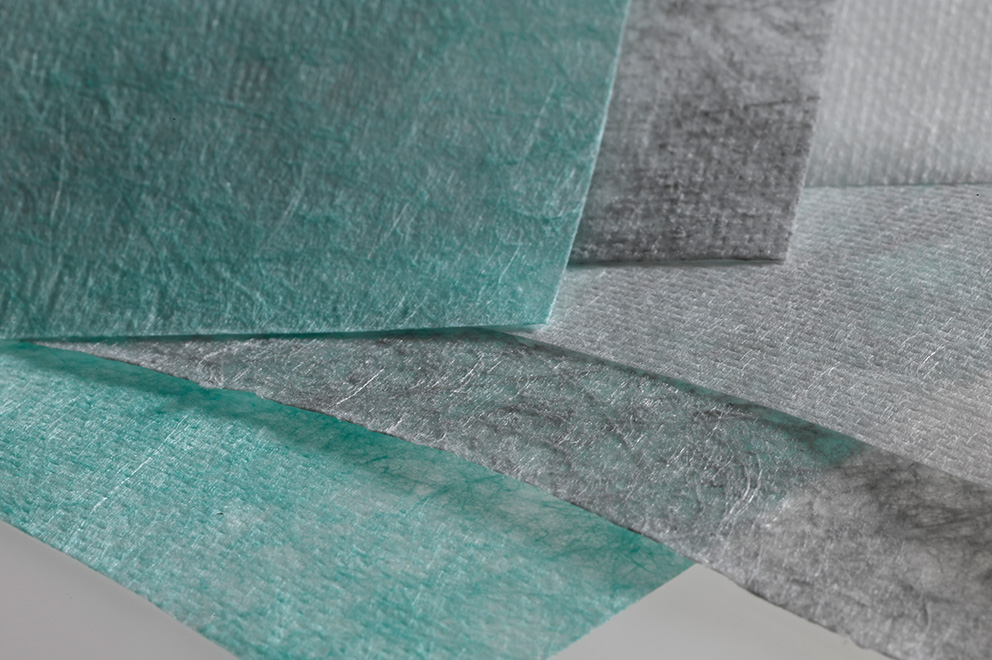

- Synthetic Nonwovens - Cranemat™

- Glass Nonwovens - Craneglas™

- Cellulose Nonwovens / Paper

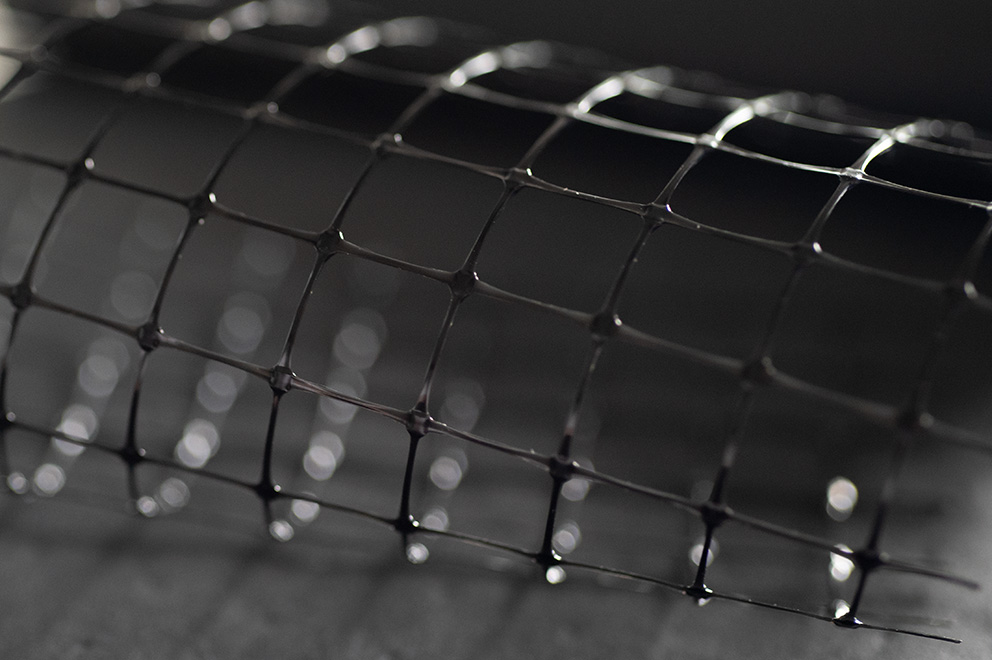

- Extruded Diamond Nettings - Naltex™

- Extruded Square Nettings - Conwed™

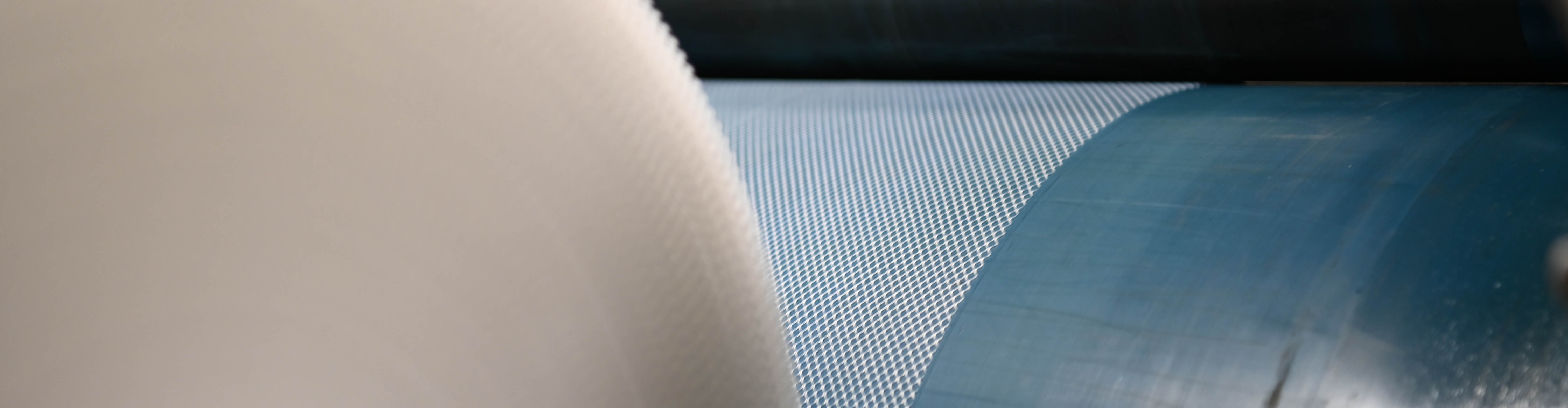

- Apertured Films - Delnet™

- Rigid Tubes & Sleeves - Conwed™ & Naltex™

- Cores & Machined Parts - Coretec™

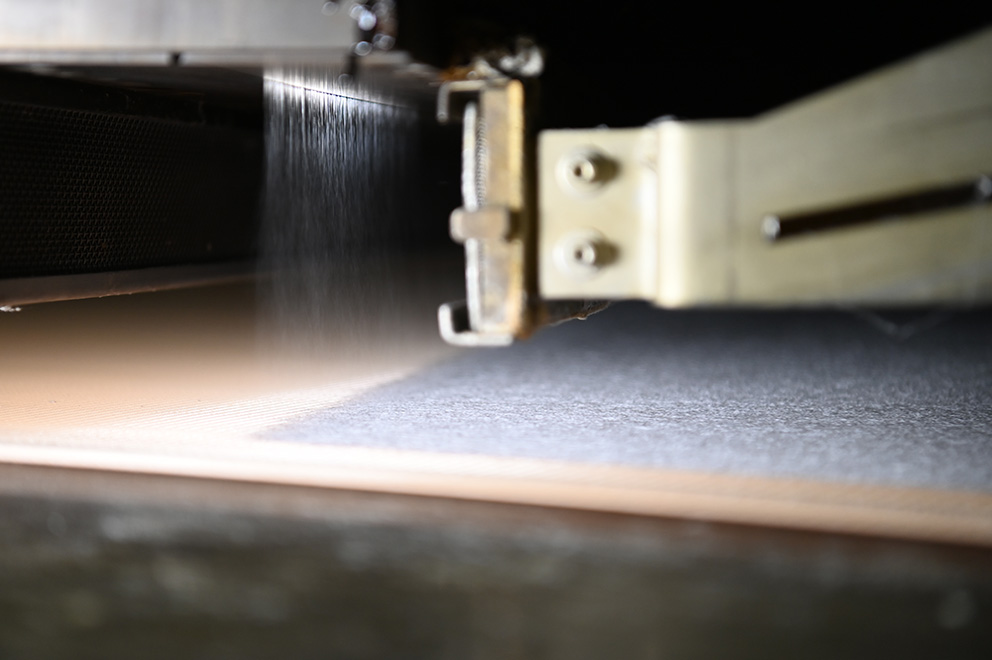

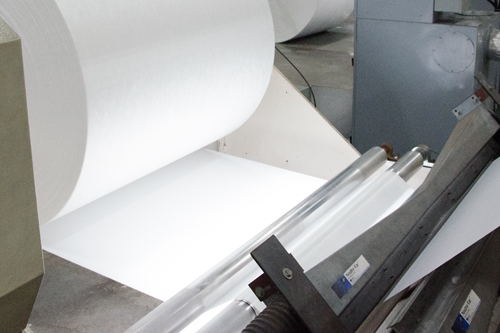

- Saturation

- Lamination

- Trade Shows

- News

- Contact