OUR TECHNOLOGICAL ADVANTAGES

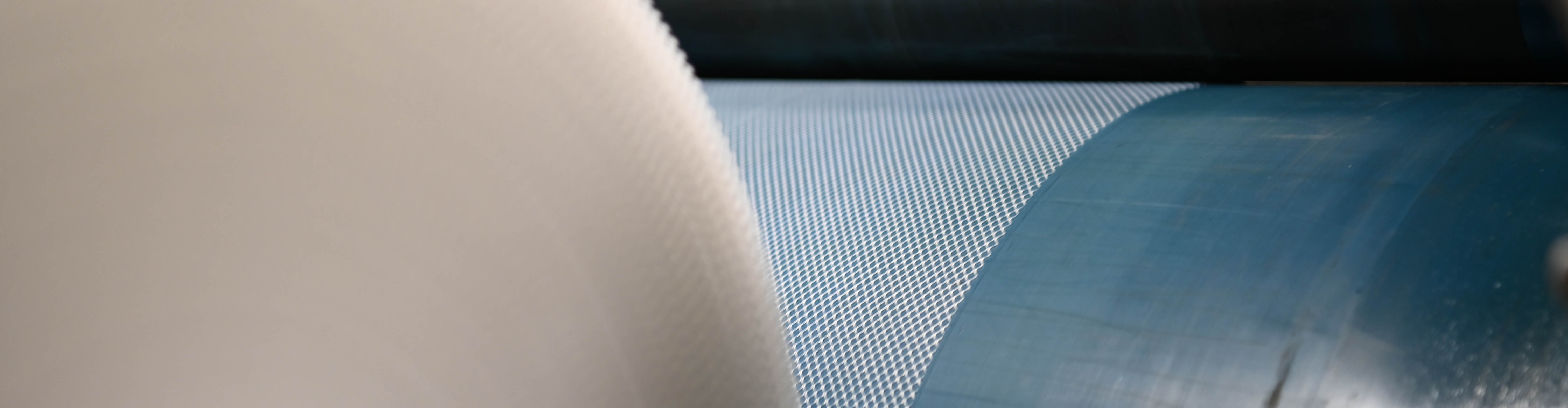

Naltex™ Diamond Netting is an extruded, diamond, bi-planar mesh netting with bonded strand intersections. It is widely utilized in many filtration applications and industries.

Naltex™ nettings feature a lightweight construction that enables users to achieve greater surface areas without increasing weight or compromising strength and durability. These materials can be used as pleat supports, providing our customers with the necessary support structure for their filter element. This additional layer of protection ensures optimum performance by preventing clogging or blockage from occurring within the filters. With these specialized netting products from GESSNER, you can enjoy improved results in your filtration processes while also reducing costs associated with waste removal and product contamination.

We offer many polymer options such as Nylon, Polyester, and fluoropolymers for high temperature and harsh chemical applications.

PLEAT SUPPORT

Naltex™ Diamond Netting is an industry-leading diamond netting technology and can be used as a pleat support for many liquid & air filtration applications. It’s bi-planer structure provides defined flow channels that prevent pleats from pinching to increase the lifespan of any pleated filter.

We offer many polymer options such as Polypropylene, Nylon, Polyester, and fluoropolymers for high temperature and harsh chemical applications.

FEED SPACER

Naltex™ Feed Spacers support and protect thin film composite (TFC) membranes in RO and other spiral wound dairy and water filtration element. They improve the performance through optimized channeling that enhances fluid flow which reduces pressure requirements. Our customizable strand alignment achieves the turbulence needed to protect and maintain system membranes. Used in nearly all TFC membrane filtration applications, ranging from home drinking water to waste water and industrial process to food & beverage and medical filtration.

We provide a full line of custom-designed Naltex™ feed spacers with varying geometries, specialty resins and optimal flow characteristics to meet your flow geometry, temperature, structural and manufacturing requirements.

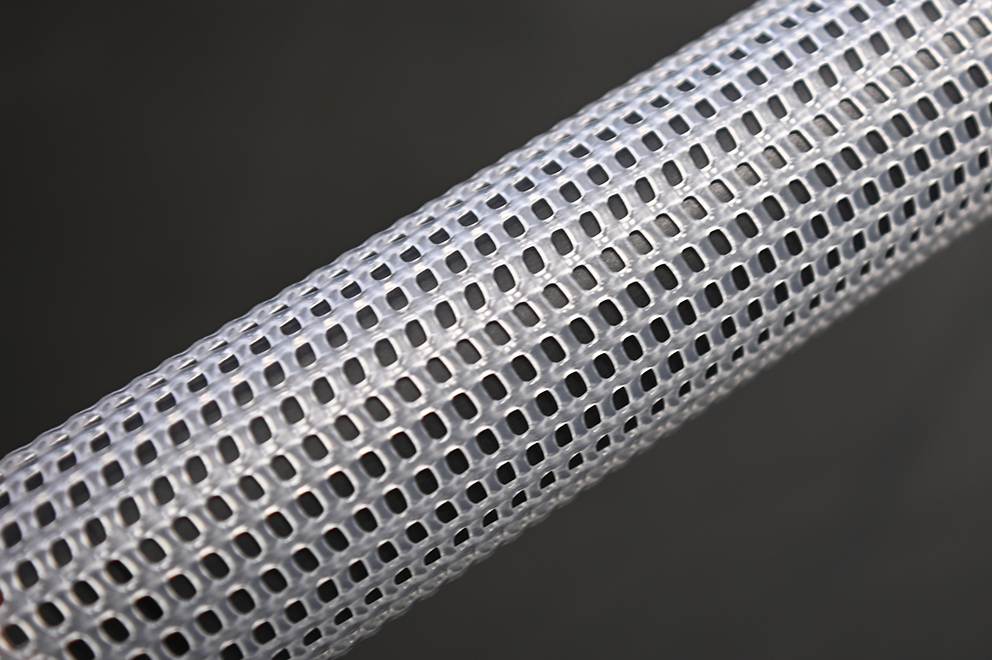

EXTRUDED CAGE & PART PROTECTION

Naltex™ Extruded Cages & Cores are ideal for support, containment and separation. They provide strength and rigidity to protect delicate media. Manufactured following a similar process as our extruded netting.

They are compatible with other materials and tailored to specific requirements.

Naltex™ Extruded Sleeves can be supplied in cut lengths and are available in unique styles that provide different levels of protection.

Learn more about our Naltex™ Sleeves