MEMBRANE CASTING SUBSTRATE

Cranemat™ are polymeric wet-laid, calendered non-woven, manufactured in Pittsfield, MA, USA. It is a membrane support substrate of choice, specified by membrane manufacturers world-wide. It has a reproducibly smooth uniform surface and controlled porosity that allows for high quality membrane casting.

Reverse osmosis membrane backing paper is a specialty paper used to support a reverse osmosis membrane during the filtration process. It provides stability, reduces fouling, and helps prevent premature membrane failure. The material typically used for this type of paper is polyester, which has excellent chemical resistance properties and mechanical strength.

The paper is designed in such a way so as to maximize the efficiency of the reverse osmosis process by providing an even pressure distribution that allows for consistent flow rates of permeate water. Additionally, it can help minimize fouling by protecting the surface of the membrane from debris or particles that may otherwise cause blocking or clogging. Furthermore, its waterproof nature helps prevent backwashing and leakage from occurring, further bolstering the performance of the RO system.

It has been used across the membrane filtration spectrum including Microfiltration, Ultrafiltration, Nanofiltration, Reverse Osmosis, and other specialty applications. Critical characteristics such as porosity, thickness and basis weight, as well as roll width and length, are routinely tailored to meet customer’s specific needs. The employees of GESSNER pride themselves in caring about the success of their customers, being responsive to customer needs and providing an excellent product in a timely fashion.

Applications like Juice and Dairy processing can deal with thicker more viscous fluids, as they separate out solids or proteins, perhaps under higher pressures, requiring frequent cleaning cycles. A more robust, stiffer membrane is often necessary to handle these challenging conditions. These membranes require a specialized backing fabric which can hold up to their demanding process parameters. Our technologies also offers stronger membrane backing substrates with higher basis weight and thicker caliper, optimized for excellent membrane adhesion, for these and other specialty applications.

Do you want to learn more? Watch our Cranemat™ YouTube Video

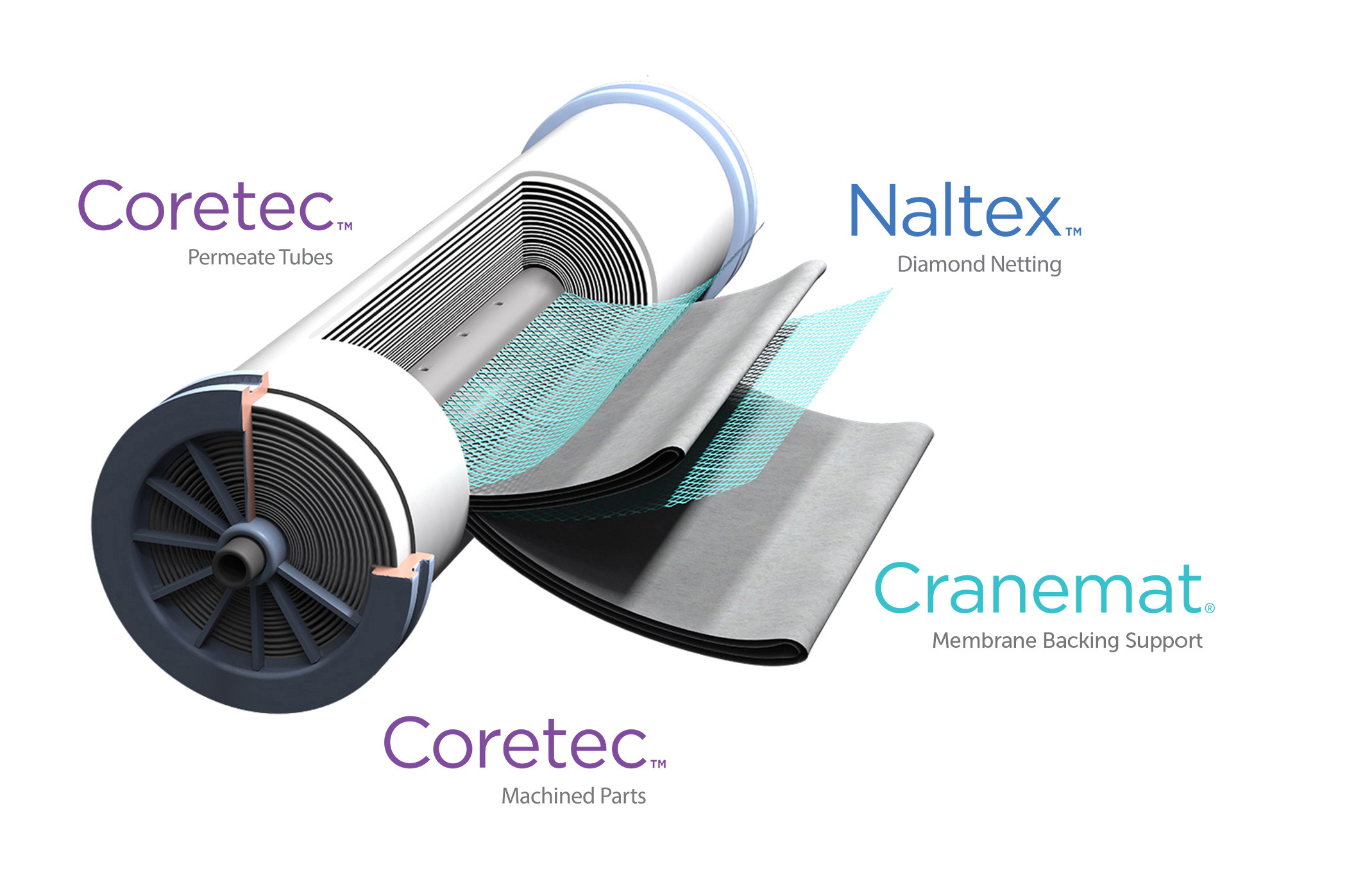

FEED SPACERS

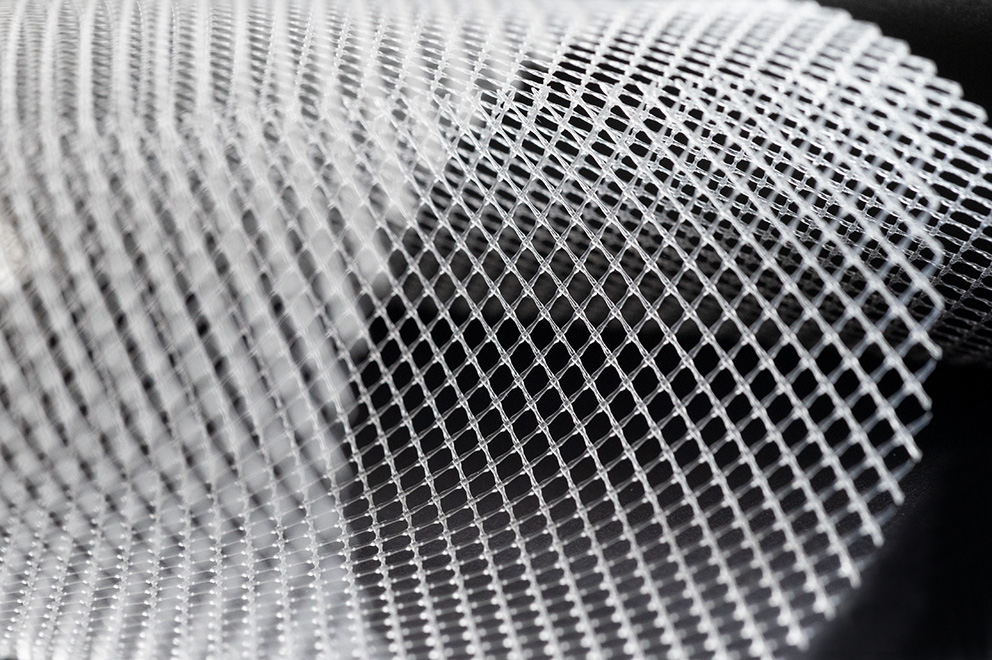

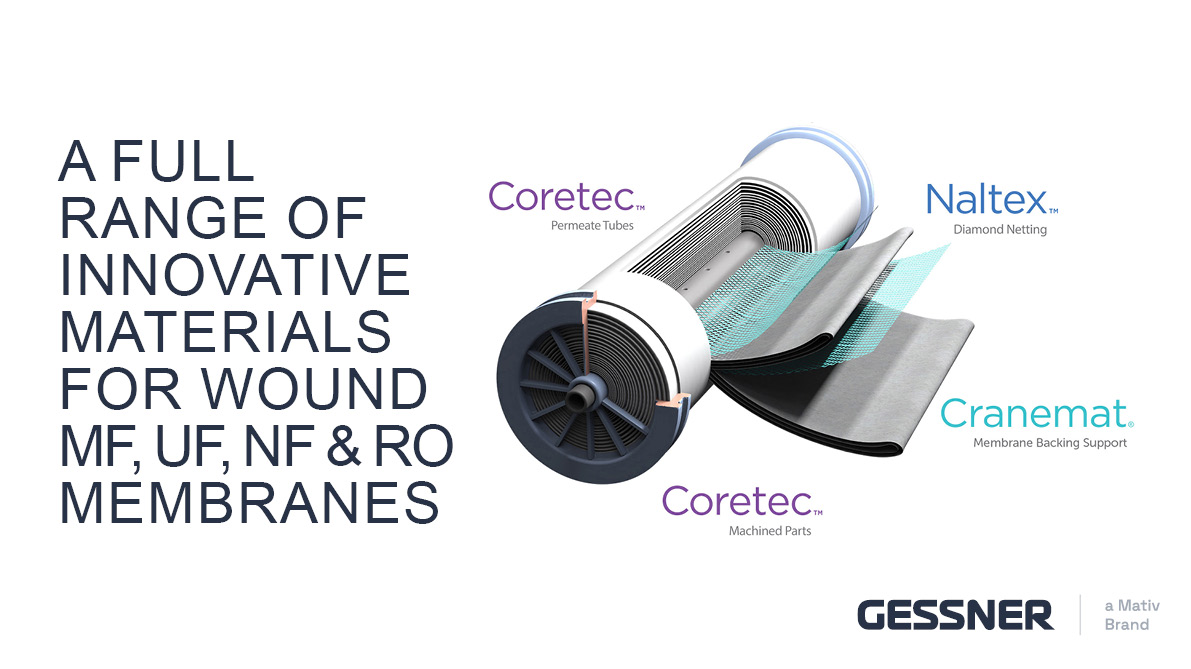

For 70 years Naltex™ Extruded Netting, our premier diamond net, has delivered high-performance results in environments needing filtration, separation, and protection.

The biplanar configuration of Naltex™ Extruded Netting allows excellent flow as feed water spacers in Reverse Osmosis (RO) applications. Specific strand alignment achieves the turbulence needed to protect and maintain the systems membranes. In addition to RO applications, Naltex can be used in many industrial applications including bags and racks for food processing and plastic mesh for protection and packaging applications. Naltex is also an ideal composite flow media for resin distribution in applications like wind turbine blade manufacturing.

Naltex™ diamond mesh continues to improve the process of extruding through counter-rotating die heads. Over the years we've introduced nets with new resins, varied strand count and cross section, and a range of strand angles, offering customers different looks, feels, strengths and additional functionality. We custom-develop extruded netting to meet your specific industrial performance requirements for demanding applications in the filtration market.

Naltex™ Feed Spacers, a bi-planar mesh with thermally bonded strand intersections, is the most widely utilized net in the filtration industry for feed spacers. Specialized engineering-grade Naltex™ nets have unmatched performance in high-end filtration systems. Our premier line of Naltex Feed Spacers support and protect thin film composite (TFC) membranes in RO spiral wound element filters. Filtration manufacturers around the world seeking high performance feed spacers turn to our full line of custom designed diamond netting with varying geometries, specialty resins and optimal flow characteristics. Naltex™ Feed Spacers are used in nearly all TFC membrane filtration applications, ranging from HRO to municipal water and industrial process filtration.

Learn more about our Naltex™ Feed Spacers

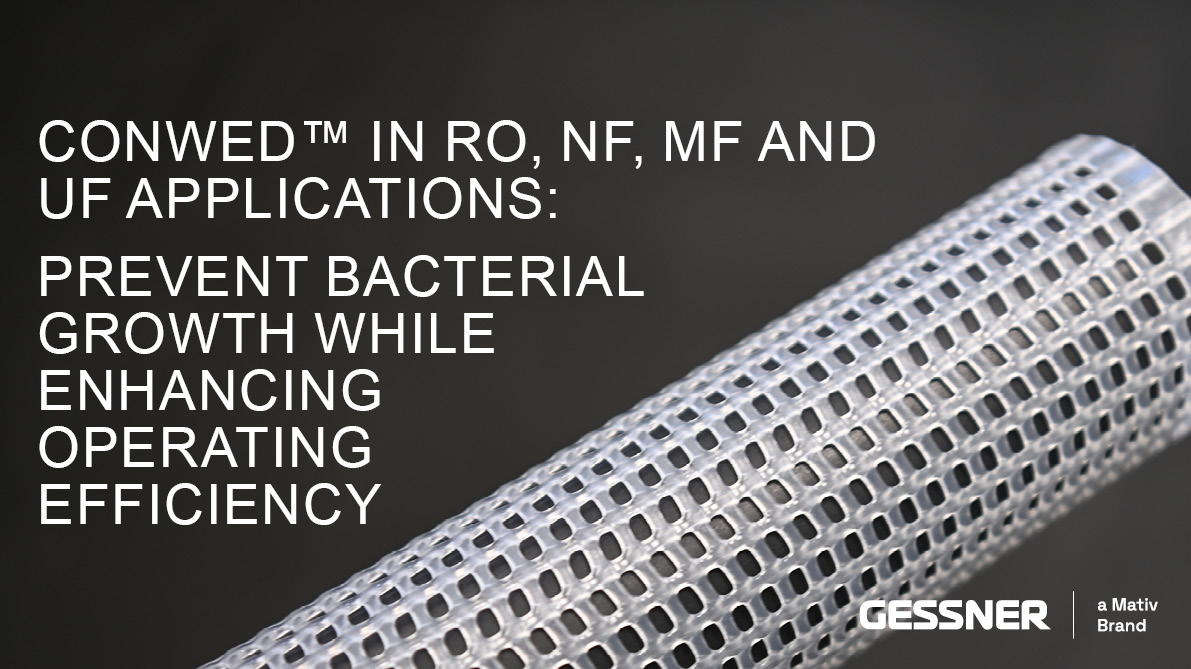

SUPPORTIVE OUTERWRAPS

Conwed™ extruded square nettings, utilized in Reverse Osmosis applications, induce turbulent flow on the membrane's external surface, effectively minimizing areas where bacteria could typically multiply. This inventive application of netting not only hinders bacterial proliferation but also bolsters the overall efficacy of water filtration systems by preserving a pristine membrane surface for peak filtration. The netting's sturdy structure and top-tier performance render it an indispensable element in these applications. Its design facilitates exceptional water flow while delivering the required structural reinforcement to the membrane, thereby ensuring its durability and extended lifespan. Moreover, Conwed's extruded square nettings' adaptability allows them to be customized to meet specific needs, making them a flexible solution for a diverse array of other industrial and consumer applications.

PERMEATE TUBES

Coretec™ Permeate Tubes include a wide range of high-performance components, made from advanced engineering-grade resins and stainless steel. Our filtration products include center tubes for reverse-osmosis water filters, feed spacers, cores, pressure vessels, machined parts, adapters. and interconnectors. Coretec high performance permeate tubes are made from engineering grade resins and are custom designed to deliver unmatched performance and quality. Coretec permeate tubes are used in a wide variety of spiral wound membrane filters ranging from small HRO products up to large volume municipal and industrial membrane systems used in water and process filtration applications.

MACHINED PARTS

Coretec™ Machined Parts are made from engineering grade materials and are custom designed to deliver unmatched performance and quality. Uses include a wide variety of spiral wound membrane filters ranging from small HRO to large volume municipal and industrial membranes for both water and process filtration applications.