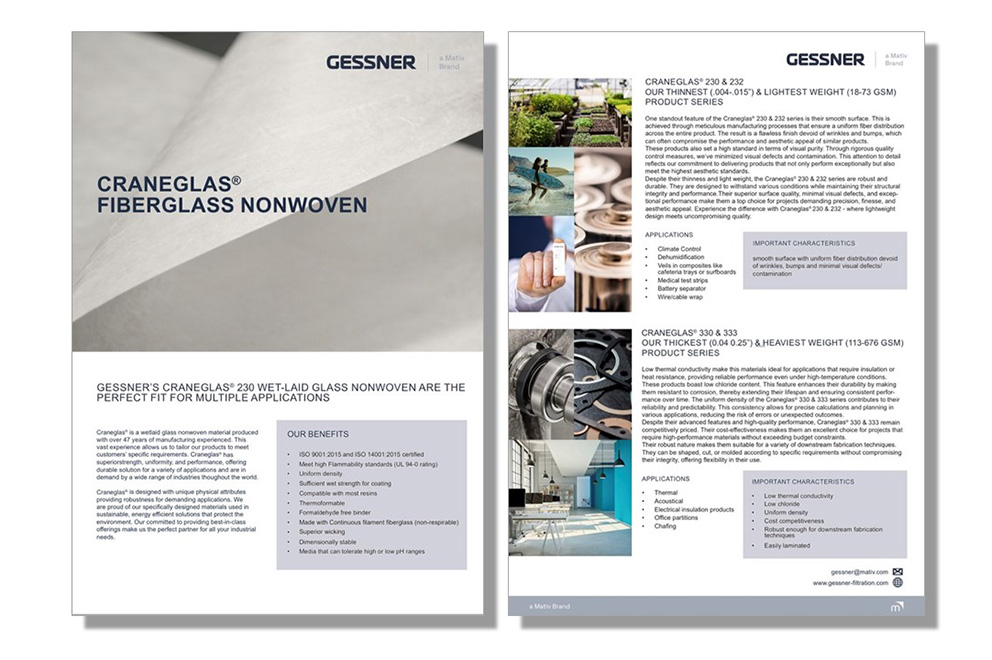

VERSATILE GLASS WET-LAID MATERIAL FOR SUPERIOR PERFORMANCE

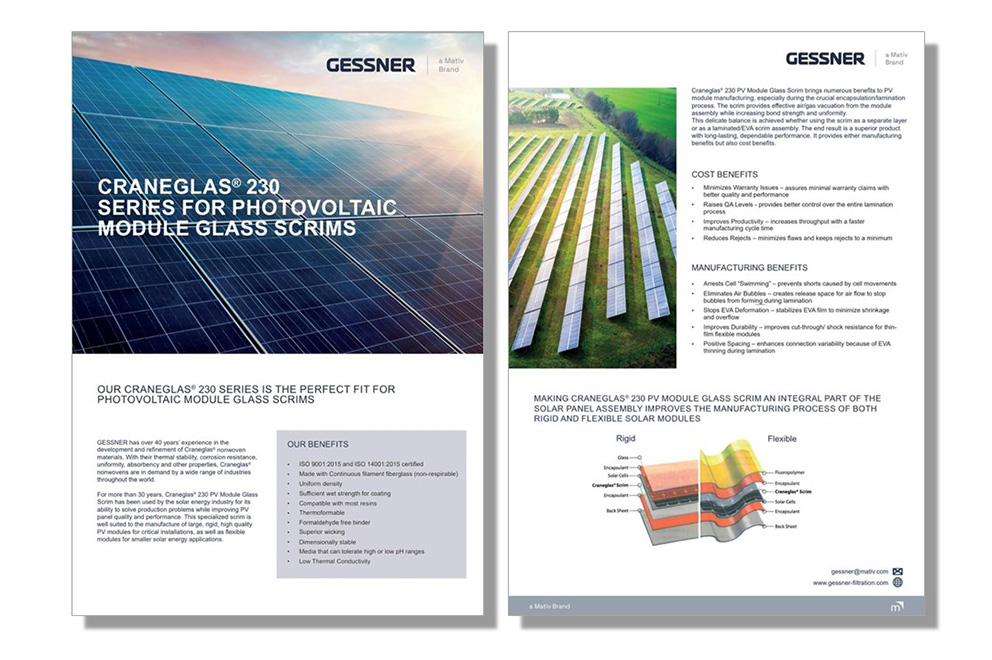

CRANEGLAS™ is a wetlaid glass nonwoven material produced with over 47 years of manufacturing experienced. This vast experience allows us to tailor our products to meet customers’ specific requirements. Our glass wet-laid nonwoven offers superiorstrength, uniformity, and performance, offering durable solution for a variety of applications. With unique physical attributes providing robustness for demanding applications we are able to offer a material which is able to diver highest performance even in roughest conditions.

We are proud of our innovative materials being used in sustainable, energy efficient solutions that protect the environment. Our committed to providing best-in-class offerings make us the perfect partner for all your industrial needs.

BENEFITS OF CRANEGLAS™

- Manufacturing Flexibility: Smaller minimum order quantities allowing customers to place orders according to their requirements. This makes it easier for them to manage their inventory and meet their production schedules.

- Customizable: While we offer many standard grades, we routinely modify the basis weight, thickness and formulation if needed to optimize the product performance to meet the needs of each specific customer. This ensures that they get the desired performance and functionality needed. CRANEGLAS™ can also be easily cut to a variety of widths or sheeted according to requirements, making it highly versatile and adaptable to a wide range of applications.

- Durability: The specialty binders we offer provide enhanced thermal stability, chemical resistance, and absorbency. This means that our products can withstand extreme temperatures, harsh chemicals, and high humidity, making them ideal for use in harsh environments. Customers can trust that our products will perform consistently and reliably under challenging conditions.

- Energy Efficiency: Due to its low thermal conductivity, CRANEGLAS™ helps in maintaining the desired temperature as it reduces the heat transfer through the material. This results in energy cost savings and energy efficiency.

- Engineered Safety: The superior thermal / flammability resistance of CRANEGLAS™ provides an added layer of safety in various applications, especially in potentially hazardous environments.

- Onsite R&D staff: Provides excellent support and rapid turnaround to partner in the development needs of both new and existing customers along with supporting academic research for university & organizations worldwide.

These features and benefits of CRANEGLAS™ make it a reliable and cost-effective option for industries, businesses, and consumers alike.