OUR PRODUCTION PROCESSES

Meltblown technology is a powerful tool in the production of extremely fine, high-efficiency filter media. The size of a meltblown fiber, with a diameter less than 10µm, is significantly finer than a human hair, which measures 120µm in diameter, or a cellulose fiber at about 50µm. This level of precision gives meltblown media an edge over other filtration materials.

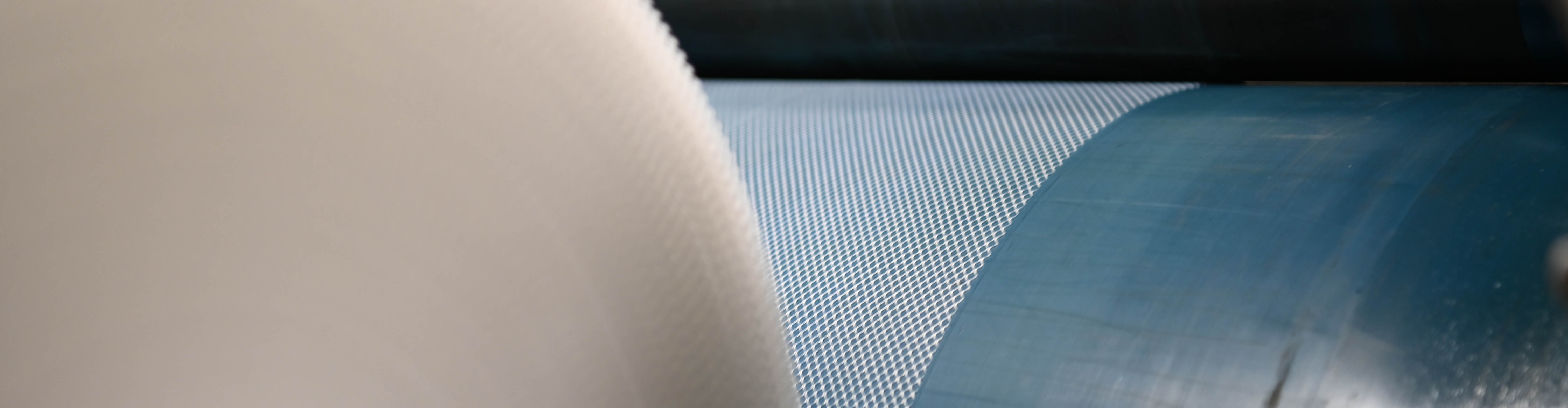

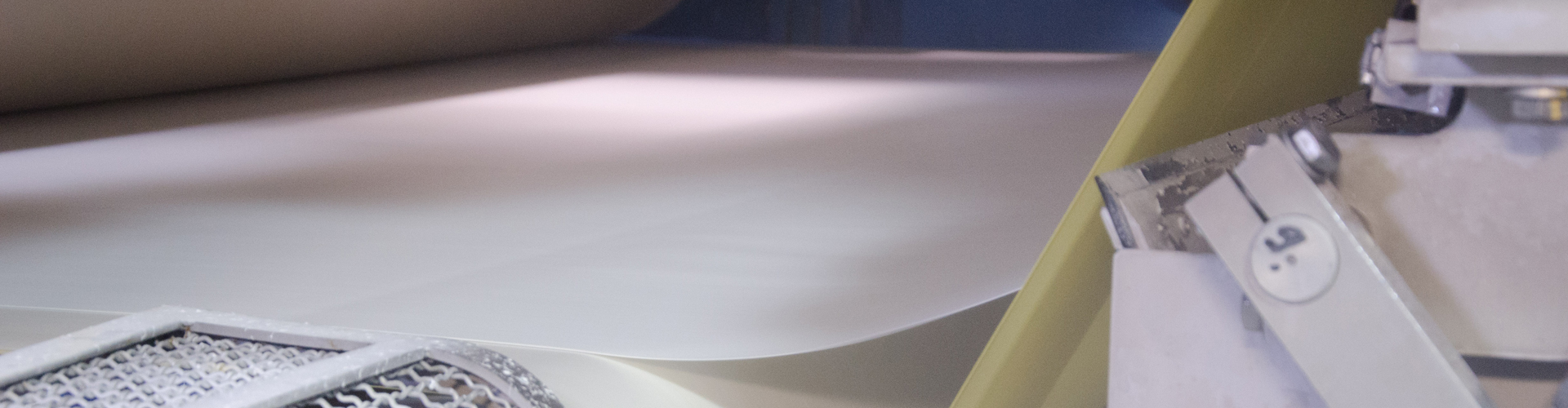

The manufacturing process starts with a thermoplastic synthetic material that is melted and pushed through an extruder filled with numerous microscopic nozzles. As the filaments exit the nozzles, they are blown by hot air while still semi-melted, expanding them into ultra-fine, continuous fibers within mere milliseconds.

This advanced dry-laid process allows GESSNER to produce media with weights varying from 15 – 400 gsm. Additionally, the meltblown can be applied directly to a carrier media such as cellulose or spunbond, creating combination media in one efficient step.

TAILORMADE TO MEET YOUR INDIVIDUAL NEEDS

Our Meltblown media offers customization options with different polymers to meet specific customer needs. Our machinery is capable of processing a wide range of materials including Polypropylene (PP), Polyester (PBT), Polycarbonate (PC), Thermoplastic Polyurethane (TPU), Polyactic acid (PLA), and various other thermoplastics.

Furthermore, we offer a broad spectrum of optional features like variable grammage, fiber diameters, surface properties, elongation, resistances (to solvents and temperature), electrostatic charge, FDA conformance, anti-bacterial properties, and UV-resistance. These options provide our customers with the flexibility to tailor the media to their specific requirements.

With our Meltblown Technology, we not only provide customized solutions for our clients but also offer our existing product ranges suitable for a variety of applications. We are committed to delivering high-quality, efficient, and tailored filtration solutions that cater to the diverse needs of our customers.

UNIQUE CHARACTERISTICS WITH A WIDE RANGE OF BENEFITS

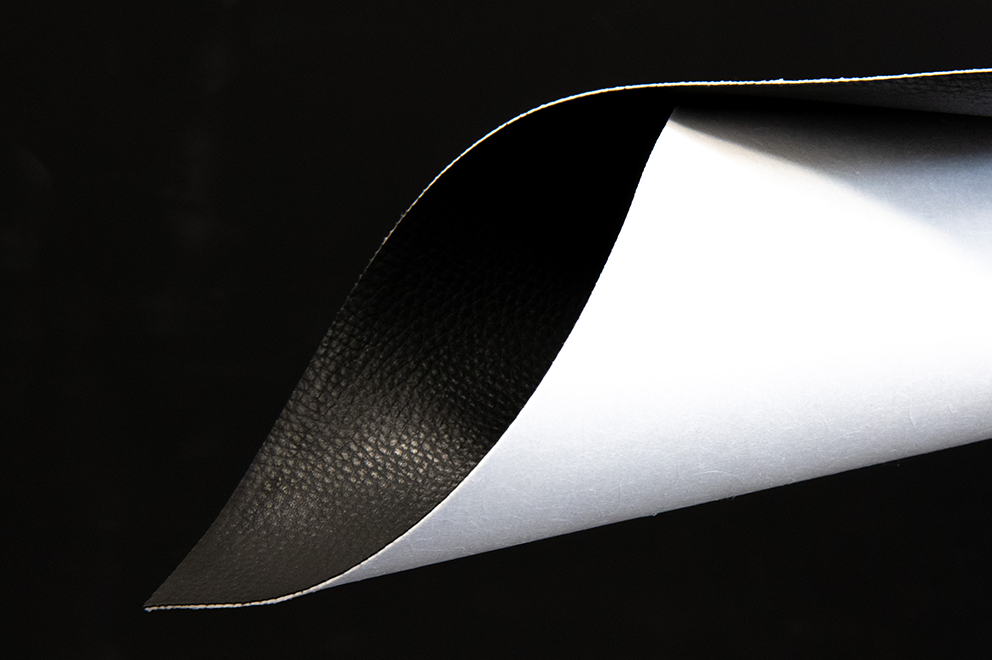

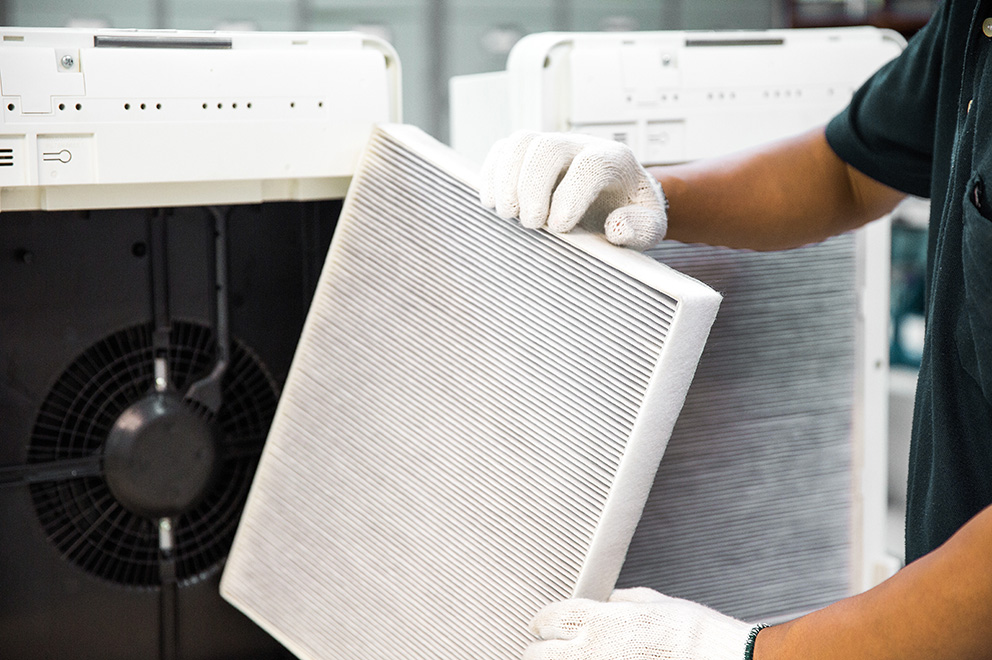

Meltblown nonwoven materials are highly effective in capturing and filtering particles. The fine fibers in the material create a dense and intricate network that can efficiently trap even small particles, making it suitable for applications such as air and liquid filtration. They provide excellent barrier properties.

The dense structure of the fibers helps prevent the penetration of liquids, microorganisms, and other contaminants, making it ideal for protective apparel, surgical masks, and other barrier applications. Despite their high filtration efficiency, meltblown nonwovens can maintain good breathability. The fine fibers allow for the passage of air, making them comfortable to wear and suitable for applications where breathability is essential, such as face masks.

Additionally meltblown nonwovens can exhibit good absorbent properties. The fine fibers quickly absorb liquids, making them useful in applications such as absorbent pads, wipes, and filtration media for oil filter elements.

We can produce our meltblown nonwovens with different fiber sizes, densities, and compositions, allowing for versatility in meeting specific requirements across various industries. They can be combined with other materials or used as standalone products, offering flexibility in design and performance.