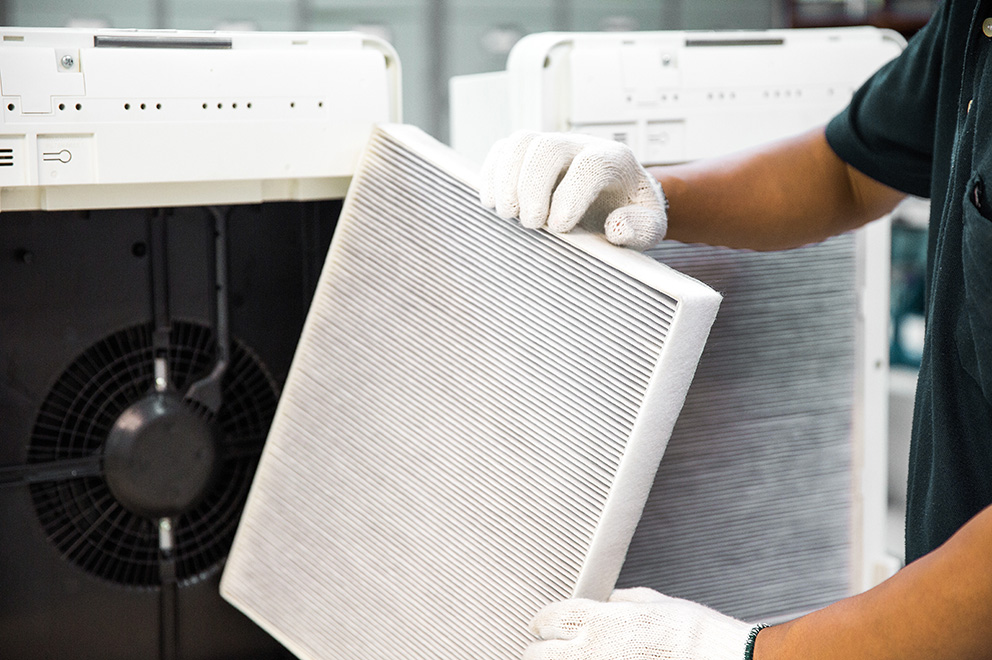

OUR FILTER SOLUTIONS FOR GAS TURBINE AIR INTAKE

FILTER MEDIA

Paper-Meltblown Combinations

A combination of cellulose based media with meltblown is an ideal choice for protecting your gas turbine from debris and other particles.

It is highly durable and resistant to corrosion, making it a better option compared to traditional woven wire mesh filters commonly used in gas turbines. The unique properties of cellulose-based media offer superior filtration efficiency and resistance to extreme temperatures, pressures, and other conditions associated with gas turbines. Additionally, the small size of the fibers ensures that the media can capture smaller particles effectively, which helps improve the overall performance of your turbine.

Meltblown-Spunbond Composite

GESSNER's meltblown-spunbond filter media composites are another option when it comes to protecting your gas turbine from contaminants. Synthetic filter media is made from polyester or polypropylene fibers that provide more efficient filtration. Synthetic filter media also has superior chemical resistance and can withstand higher temperatures than natural fibers such as cotton or wool. As such, synthetic filter media is a great choice if you need a secure barrier against contaminants while still allowing air to pass through the system efficiently.

Our synthetic gas turbine filter media are F9 approved accoring to EN779:2012 and ePM1: 80% according to ISO 16890. Our very good pleatiability results in sharp pleats. Additionally, our media provide a good air permeability to efficiency ratio, offering higher efficiency at low pressure loss. The material can be used as a static medium but also for reverse pulse applications for high dust load environments. Gas Turbine media by GESSNER are OEM approved but also available in the aftermarket.

CATALYST CARRIER

Craneglas™ glass wet-laid nonwoven material is an advanced catalyst carrier designed specifically for applications like gas turbine air intake . This innovative material boasts a thin hydrophilic structure with controlled wicking properties, ensuring optimal moisture management and efficiency. The even distribution of flow throughout the material enhances performance, while its affinity to most reacting agents makes it highly versatile. The material is engineered for easy slitting and dynamic strength, facilitating seamless downstream processing and integration into your systems.