TAILORED BONDING TECHNOLOGIES FOR PRECISION LAMINATION

PERFECT LAMINATION FOR DIFFERENT MATERIALS SOLUTIONS

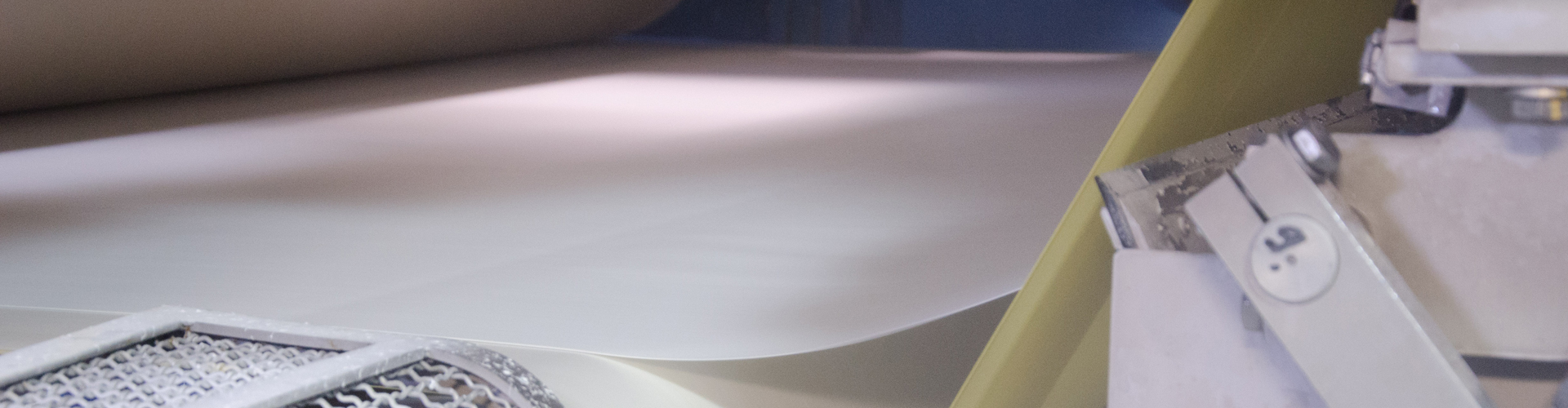

Our state-of-the-art lamination line is designed to revolutionize material processing by combining substrates such as paper, wet- or dry-laid nonwovens, and films into a versatile, multi-layered material. For a tailored solution that meets your specific needs, our three advanced bonding technologies and finely adjustable web tension system deliver precise and high-quality lamination, whether you're working with lightweight materials or high-stretch substrates.

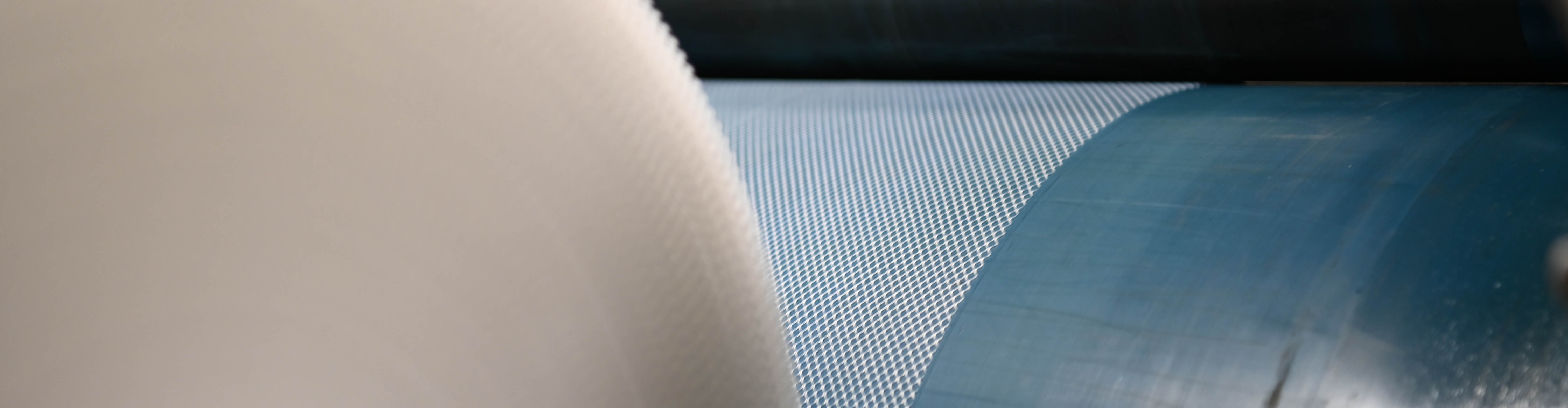

Our ultrasonic bonding system, with its dot-array pattern, enables the efficient bonding of up to five layers in a single process step, providing unmatched efficiency and productivity. Alternatively, our adhesive unit is equipped to spray hotmelt adhesive or reactive hotmelts, facilitating full-surface lamination of two layers in one seamless process step.

Our lamination technology is not just about combining layers; it’s about enhancing the functionality and value of the final product. Whether the material needs added strength, improved barrier properties, or specific functional attributes, our lamination technologies offer the versatility and precision to meet your unique requirements.