FILTER SOLUTIONS FOR POWER GENERATION

MAXIMIZE POWER GENERATION EFFICIENCY WITH OUR ADVANCED FILTRATION SOLUTIONS

Power generation is increasingly important as the world seeks to become more sustainable and reliable in its energy sources. Filtration plays a big part in the power generation process. To meet the demanding filtration requirements GESSNER offers a complete line filter media and filter components.

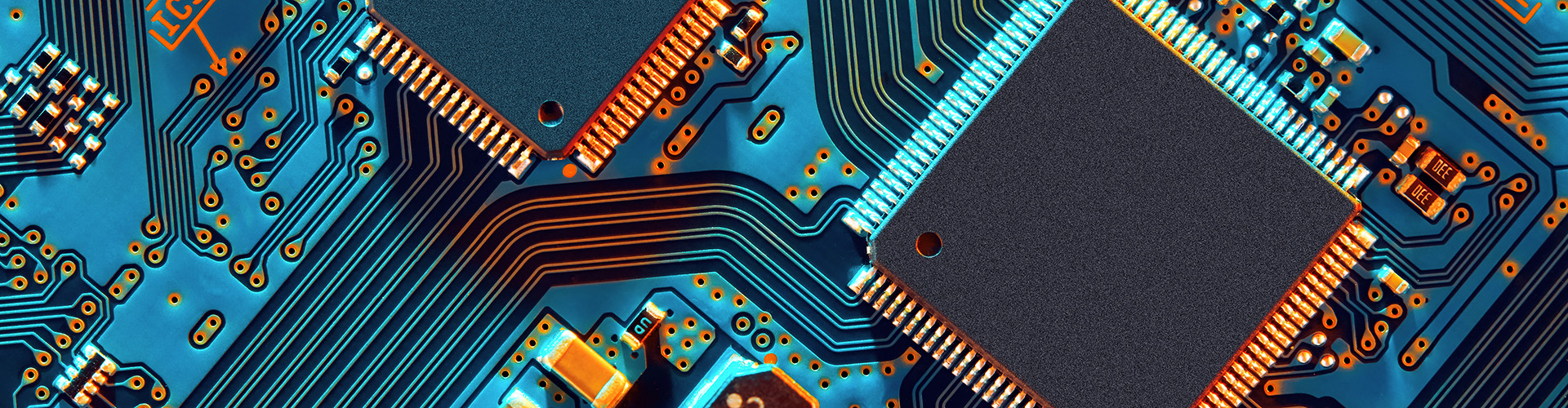

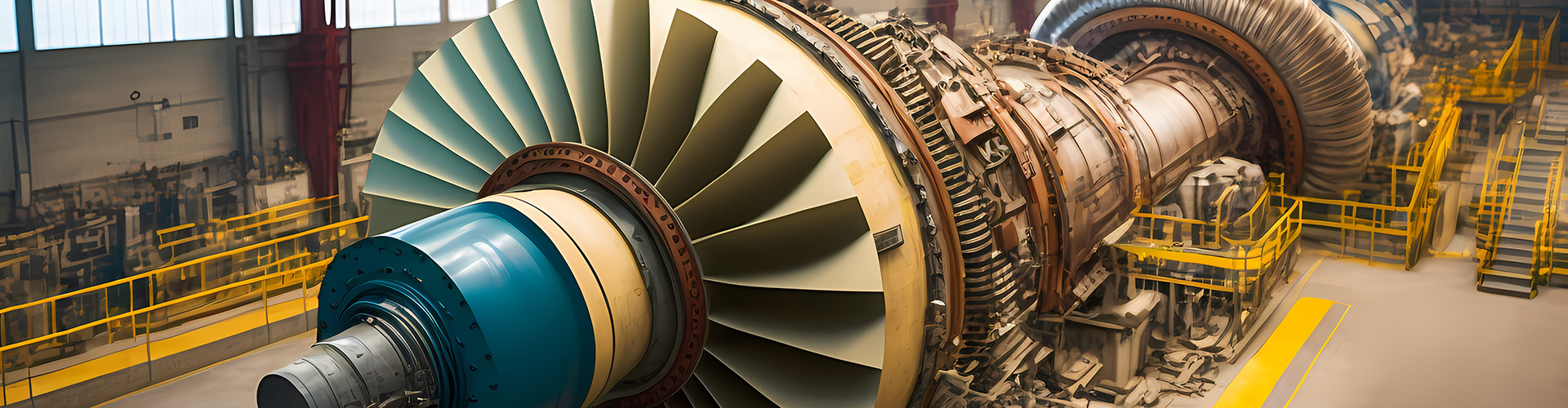

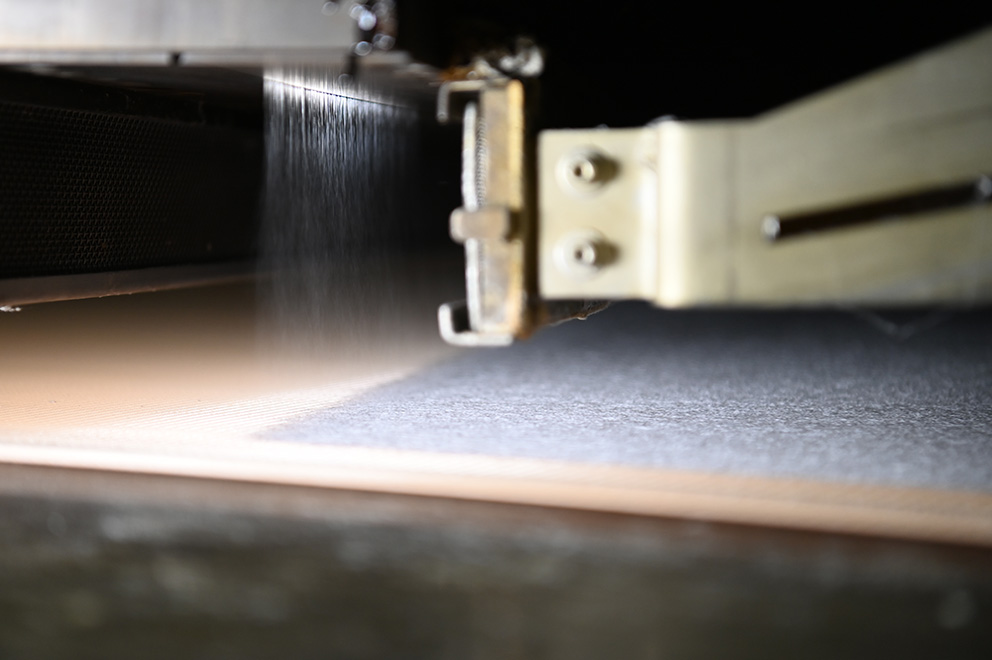

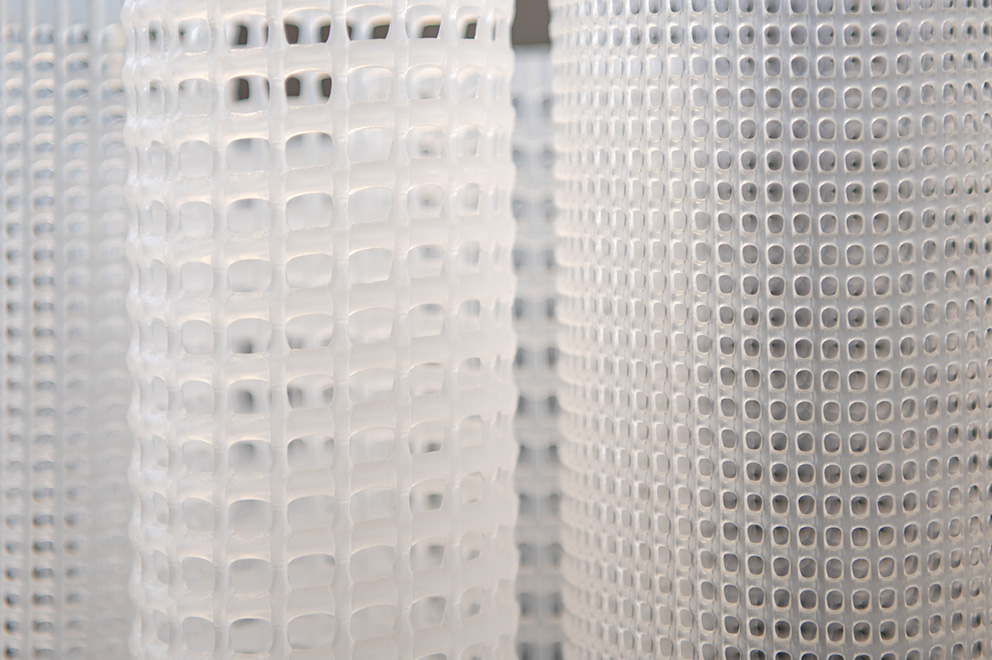

Our filter media is used to remove particulates from air or liquid streams and to coalesce liquids. In the case of power generation, typical applications include condensate polishing, liquid coalescers, gas turbine intake filters and more. GESSNER offers other filter components critical to high preforming filters. This includes sleeves, cages, and pleat supports. These support components are made from materials to meet the demanding temperatures, corrosive resistance, and life span the power generation industry requires.

Filter media and components are essential for proper functioning of power plants and generators. Proper filtering ultimately results in increased reliability, efficiency and cost saving when it comes to producing electricity.