MAXIMIZE HYDRAULIC PERFORMANCE WITH GESSNER PLEAT SUPPORT AND FILTER MEDIA

GESSNER'S SOLUTIONS FOR HYDRAULICS

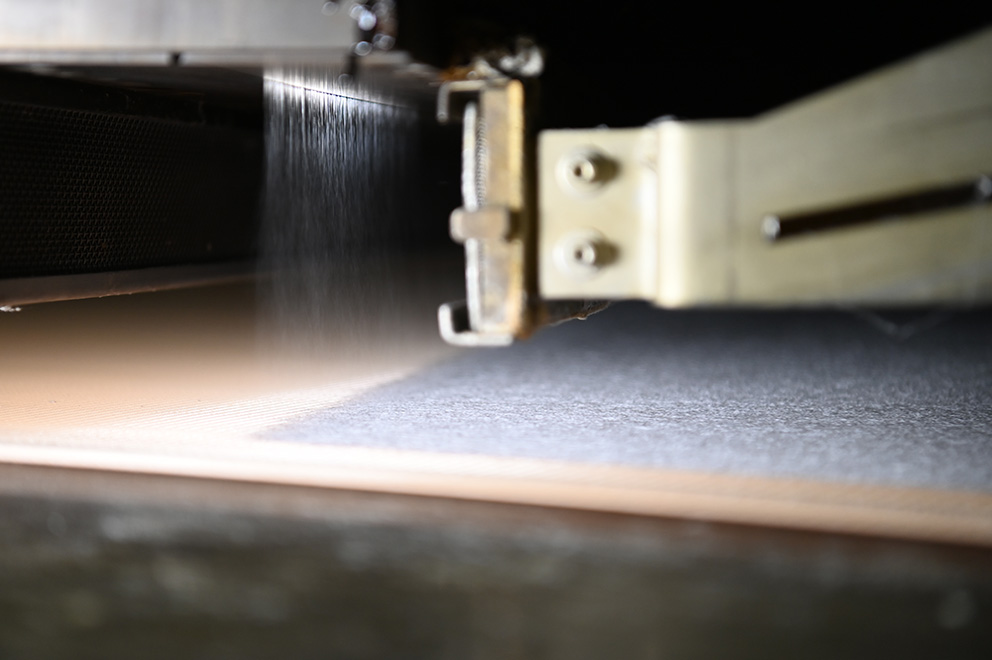

FILTER MEDIA - DELPORE™ MELTBLOWN NONWOVEN

Delpore™ meltblown media has been specially formulated for use in hydraulic oil filters. This advanced synthetic material provides superior performance compared to conventional cellulose-based filter media. It can maintain a high level of filtration efficiency while also extending the life of the filter and protecting against premature clogging. Delpore™ meltblown media is designed with a unique structure that allows it to capture particles as small as 10 microns, which is more than five times finer than other filter materials. The material has also been tested to effectively reject water, which helps prevent corrosion and wear on the system components. Additionally, Delpore™ meltblown media is resistant to chemical breakdowns caused by oils, making it an ideal solution for hydraulic applications.

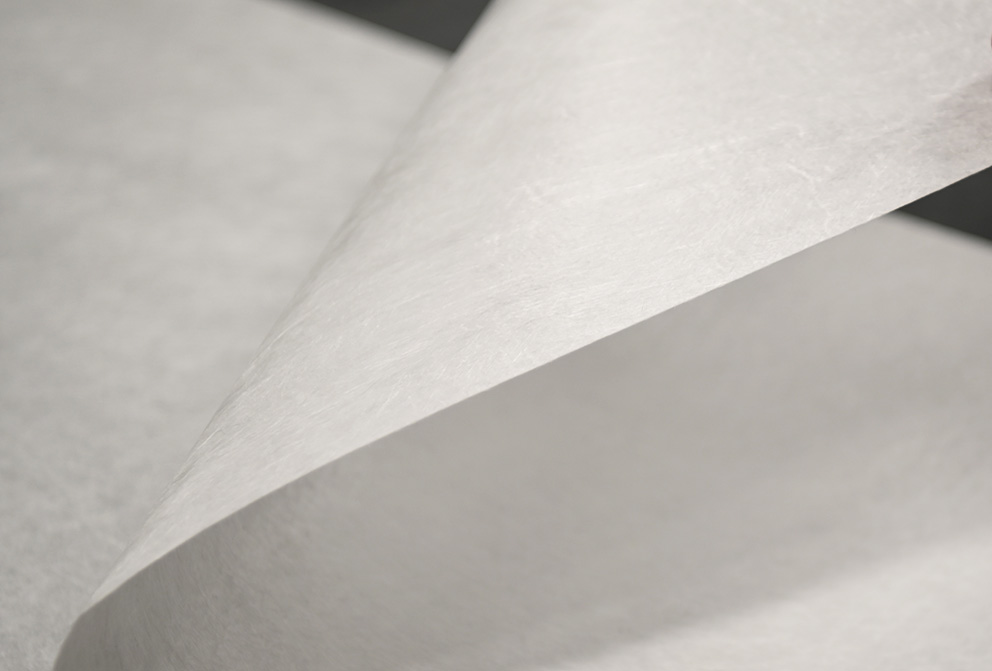

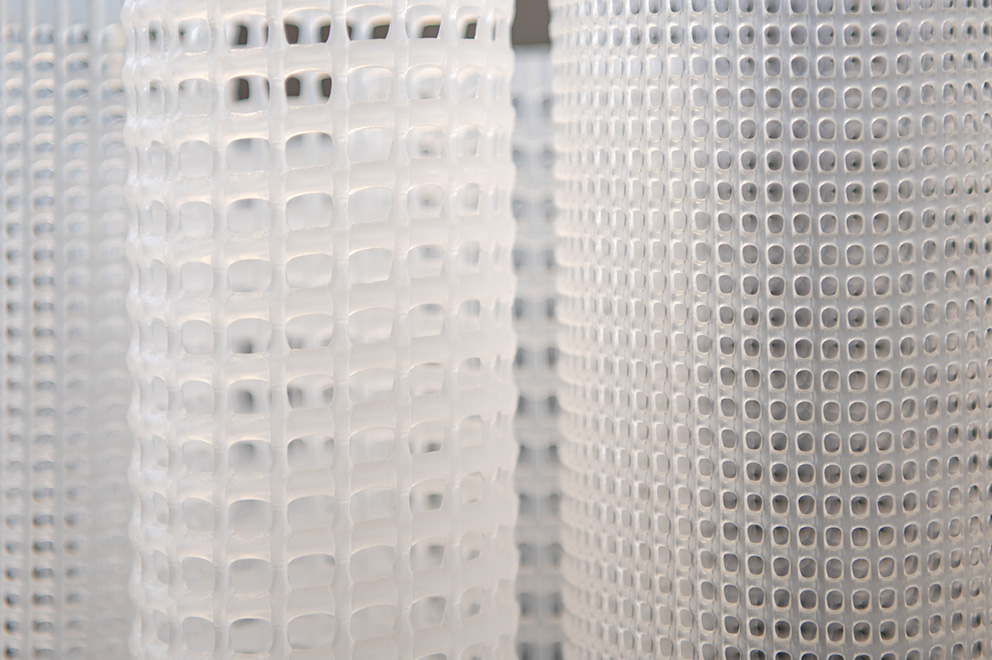

FILTER MEDIA - CRANEGLAS™ GLASS NONWOVEN

CRANEGLAS™ filter media is a type of glass nonwoven, engineered with precision to create a strong and lightweight material. It is highly resistant to wear and tear, making it perfect for applications that require durability. Additionally, it boasts excellent heat resistance properties and can withstand temperatures up to 400°C. Its superior strength-to-weight ratio make it suitable for various industrial purposes, such as construction and manufacturing. Hydraulic oil is also frequently used in combination with CRANEGLAS™, as it helps reduce friction and provide added protection against corrosion. Thanks to its versatility, CRANEGLAS™ can be easily molded into a wide range of shapes and sizes for different projects, ensuring that no matter the requirements or environment, there's a suitable solution available.

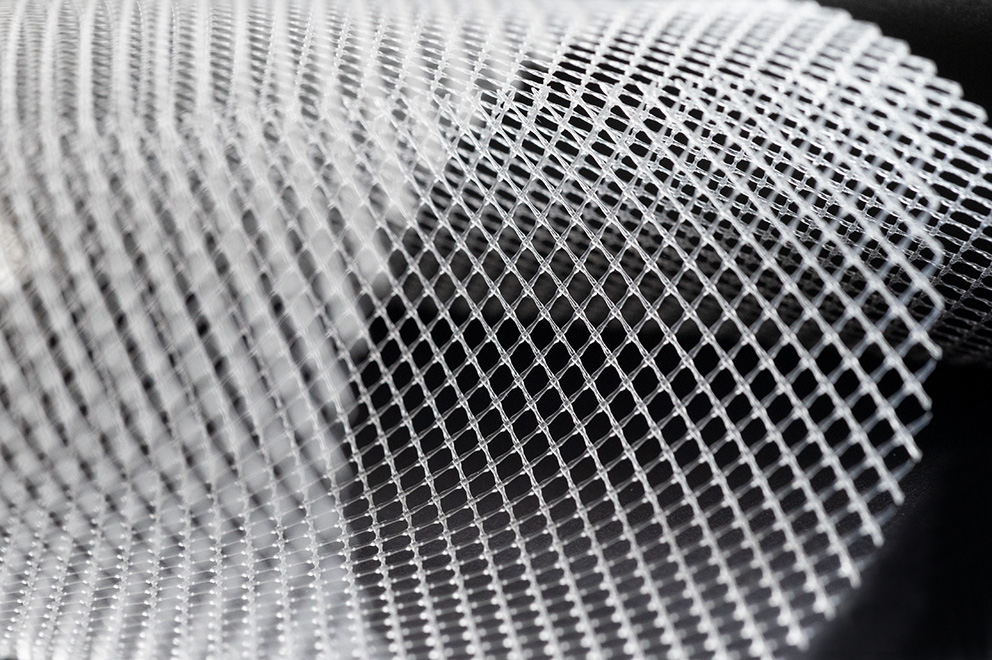

PLEAT SUPPORT - NALTEX™ & CONWED™

GESSNER's Naltex™ & Conwed™ pleat support is essential for maintaining the shape of filter elements under high pressure or corrosive conditions. Commonly used materials include polyester mesh and polypropylene mesh which offer varying levels of durability and strength depending on the application. The type of material chosen should also take into account factors such as temperature resistance, abrasion resistance and permeability requirements in order to optimize performance over time.