PEAK PURITY, PEAK PERFORMANCE:

OUR FOOD & BEVERAGE FILTRATION SOLUTIONS

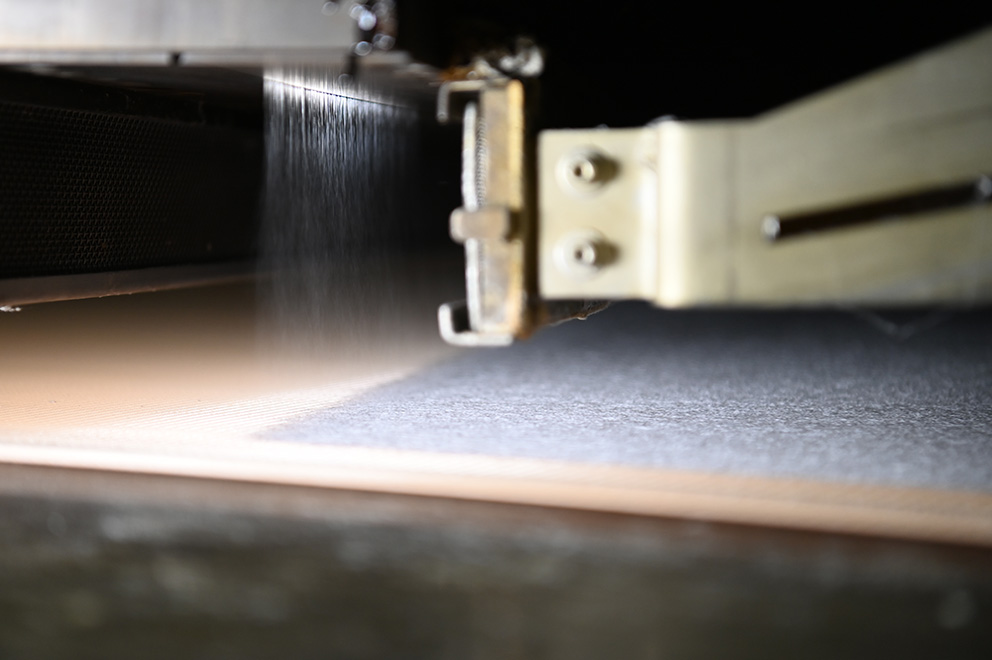

FILTER MEDIA

Delpore™ meltblown nonwoven filter media for food & beverage offer a wide range of benefits from superior quality to fluid flow efficiency. Additionally, many food and beverage filter media products are FDA-certified for use in food and beverage processing. This ensures that the products meet the standards established by the Food and Drug Administration for safety and quality. The materials used for these filter media are carefully selected for their ability to trap particles, retain flavor, reduce the effects of oxidation, and provide other beneficial properties. They are manufactured to exacting standards that enable them to handle a variety of fluids with ease. For example, they can be designed to work with liquids such as juices, beers, wines, sodas, spirits, water or any other type of liquid with ease. Additionally, they are capable of filtering particles ranging from tiny micron sizes down to larger sub-micron sizes depending on the material used.

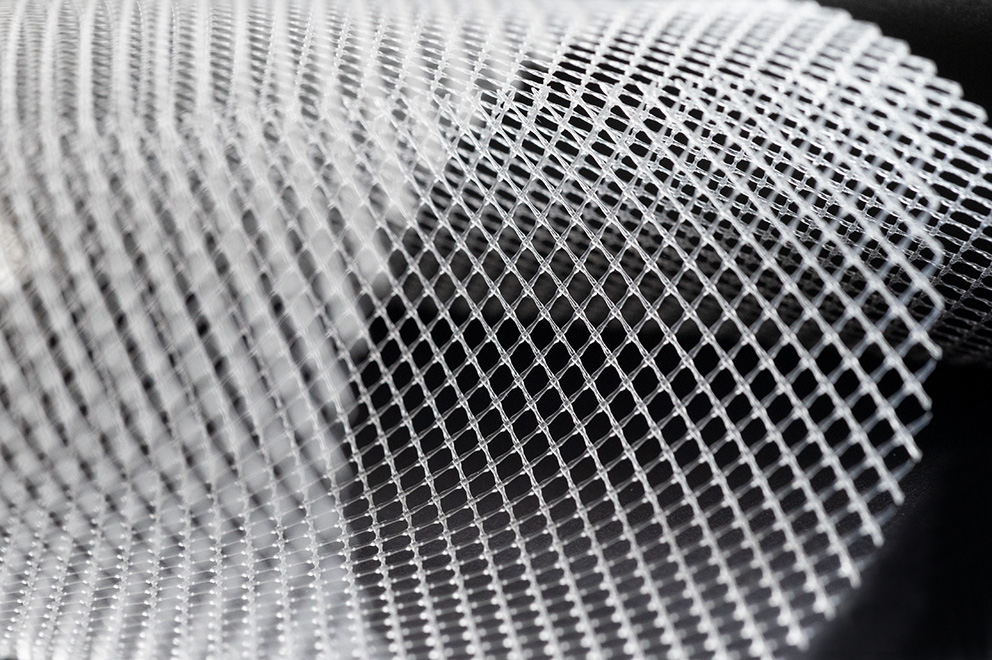

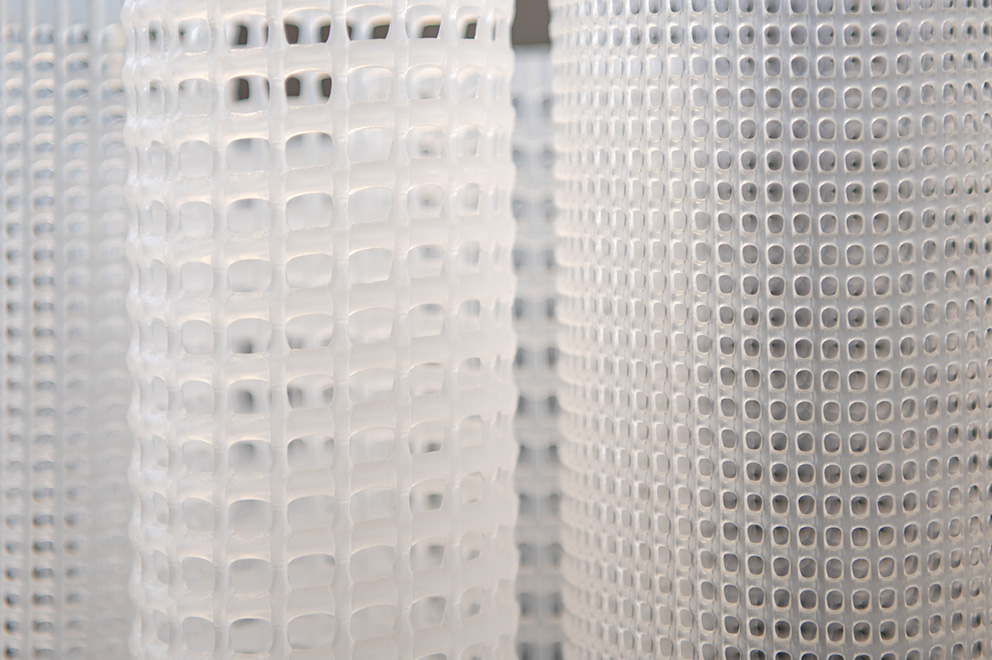

PLEAT SUPPORT

Our Naltex™ & Conwed™ pleat supports are an essential component of beverage filtration processes. They provide the necessary structural support to keep filter media securely in place, while providing a uniform seal against the housing wall, ensuring that no contaminants bypass the filter or sneak into the finished product. Made from a variety of polymers, our pleat supports facilitate precision manufacturing and efficient filtration over time. By providing more surface area for contact with particles in beverages and other liquids, these supports can extend the life of filters and seals. Beverage pleat supports also offer enhanced structural integrity due to their shape retention capabilities - meaning they can be crushed or stretched without jeopardizing their effectiveness. With proper maintenance and care, these pleat supports can deliver long-lasting results for all types of beverage filtration processes.

LEARN MORE ABOUT OUR NALTEX™ PLEAT SUPPORT