Two surfaces with one medium

Improved dust holding capacity and flame retardancy combined with tailored processing advantages

GESSNER's Innovative Asymmetric Saturation Technology: Revolutionizing Engine Air Applications

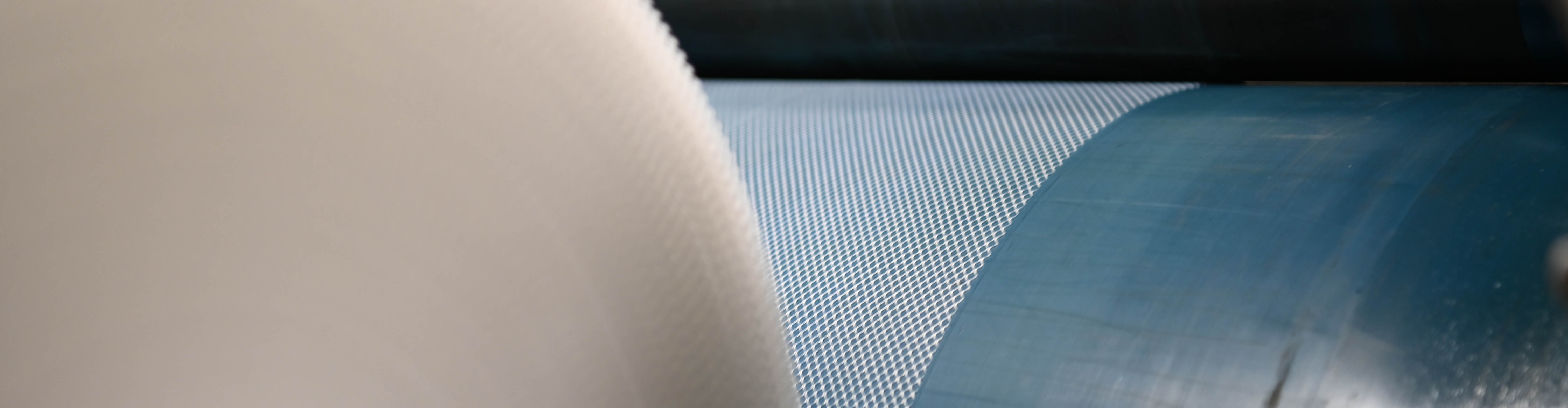

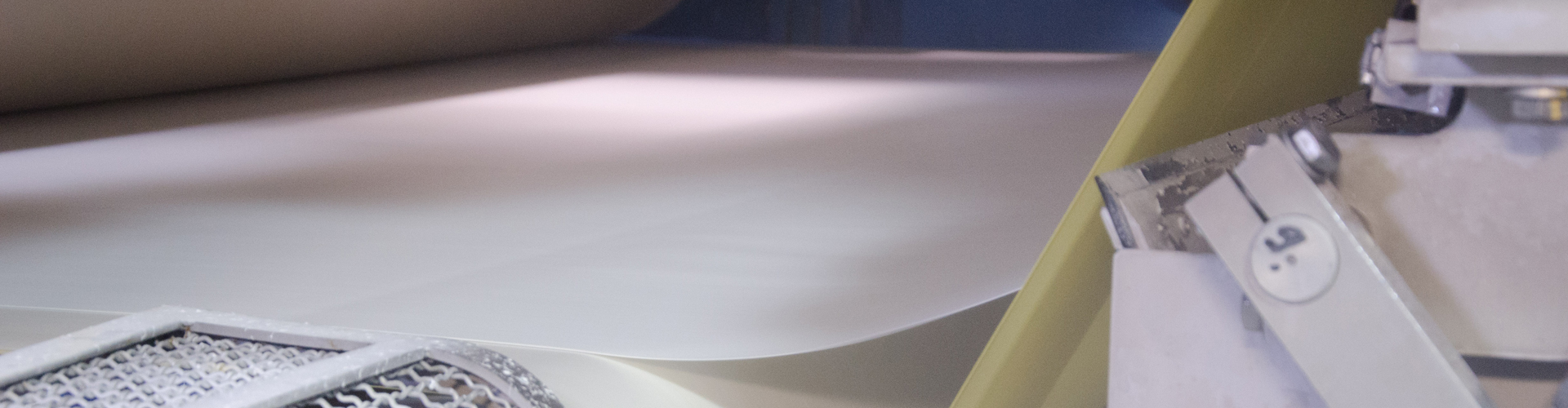

Creating a medium with two surfaces possessing distinct properties brings unprecedented benefits to both the product and its processing. GESSNER's groundbreaking asymmetric saturation technology marries the physical advantages of the filter medium with enhanced processing capabilities.

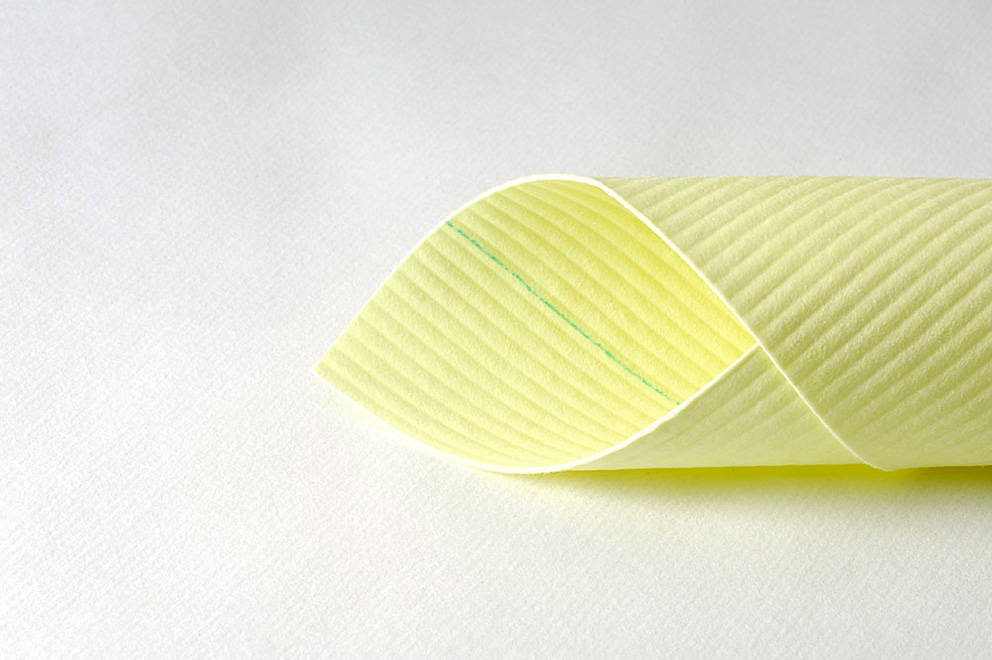

In the realm of engine air applications, it is crucial to maximize the effectiveness of the gradient in the filter medium. This is achieved by carefully selecting the binder for the upstream side. GESSNER can optimize the dust holding capacity (DHC) by up to 10% or even 20%, in conjunction with an increasing gradient, all while preserving the flame retardant function. As pioneers in formulating flame retardant resins, we ensure passenger safety in cars or trucks despite integrating additional features into our GESSNER™ medium.

The application of different resin systems on a single medium allows the incorporation of various properties into the filter element. Simultaneously, a different resin system on the clean side can offer customer-specific benefits catering to unique needs and requirements. GESSNER provides the option to incorporate properties such as softness, uncured or pre-cured surface, and stiffness.

Our asymmetric saturation process enables the customization of filter media to meet our customers' specific needs, amalgamating a variety of properties in a single medium.

These innovative possibilities contribute to the development of long-lasting, top-quality media for engine air filter elements, setting new standards in the market.