Combined advantages with asymmetric saturation

Optimized benefits of ultrasonic welding in paper processing plus curing properties through an asymmetric saturation process

Revolutionizing Paper Conversion: GESSNER's Asymmetric Impregnation Technology Enhances Ultrasonic Welding

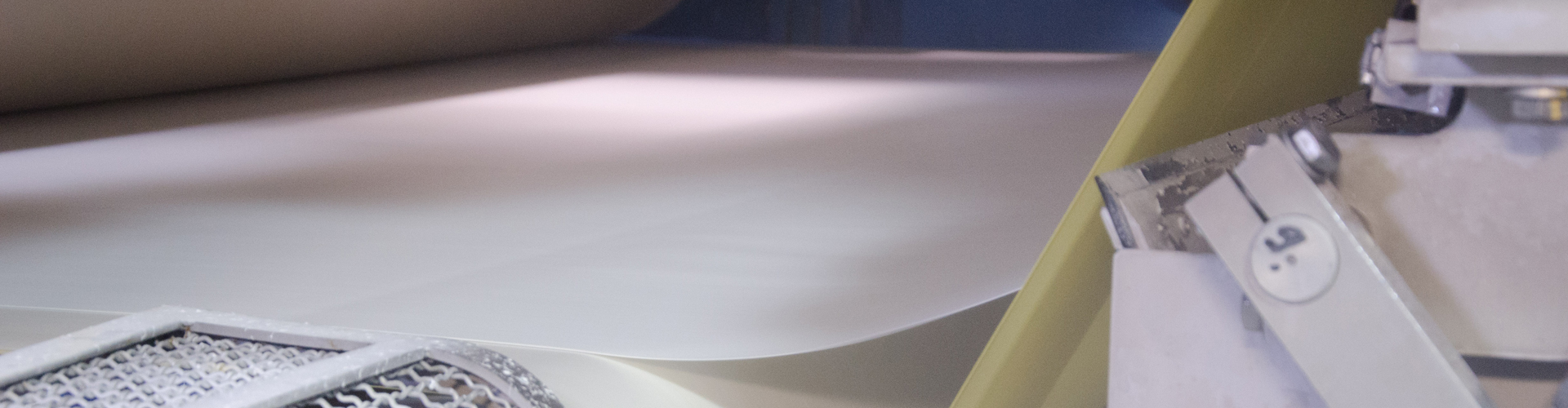

GESSNER's advanced asymmetric impregnation technology is set to transform the paper converting industry by enabling filter manufacturers to join paper through ultrasonic welding, eliminating the need for additional glues or adhesives. This innovation significantly streamlines the manufacturing process and enhances product quality.

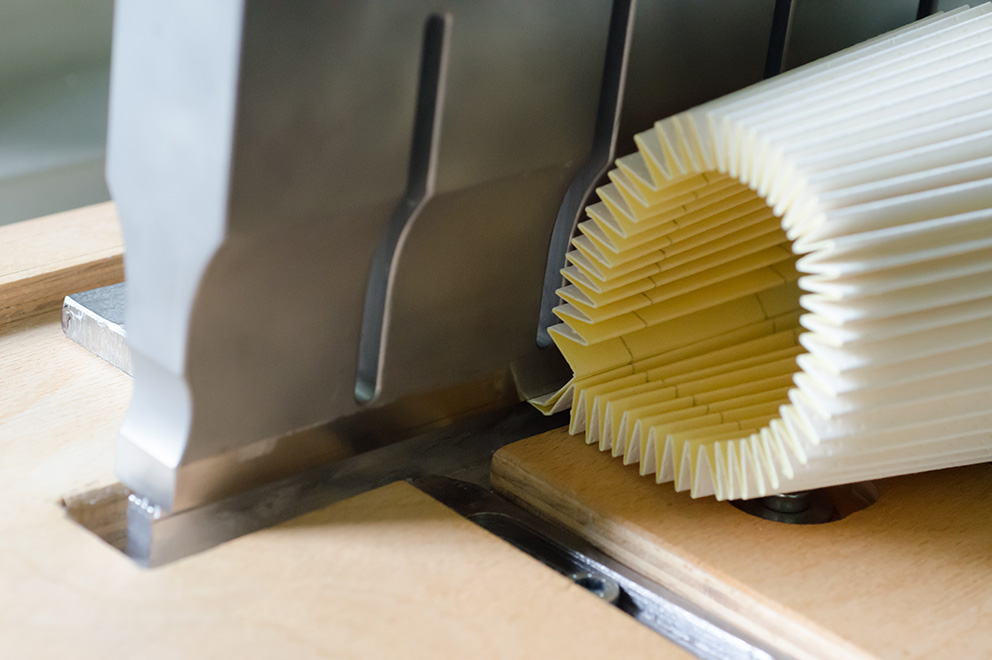

Ultrasonic welding technology is the preferred method for processors of paper products due to its superior speed compared to other welding processes. This method not only reduces production costs by eliminating the need for glue or other adhesives but also ensures clean, secure seals, resulting in a high-quality joint.

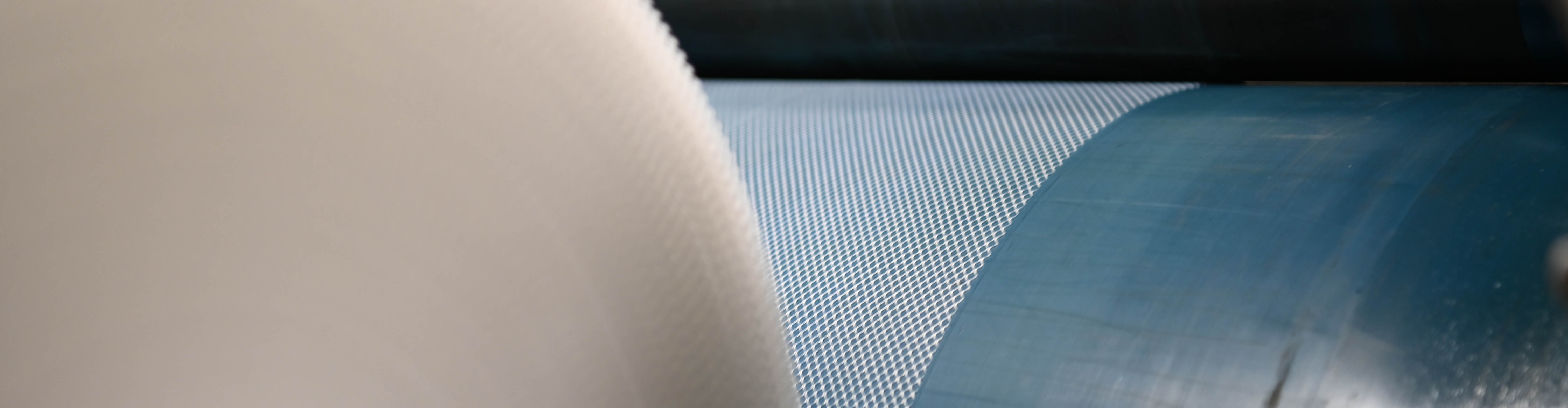

To further enhance the benefits of ultrasonic welding machines, GESSNER has engineered a material that complements these advantages. Our GESSNER oil filter media is impregnated with a cutting-edge phenolic-based resin that cures rapidly, producing a durable, continuously manufactured oil filter element.

Beyond the advantages offered by ultrasonic welding, our asymmetric saturation ensures all the necessary attributes of a superior filter medium. Characteristics such as high efficiency and Dust Holding Capacity (DHC) guarantee top-quality filter elements.

By combining efficient processing via ultrasonic welding technology with the excellent properties attained through asymmetric saturation, GESSNER media can meet individual customer requirements without compromising on further processing.