GESSNER is a pioneer in flame retardancy

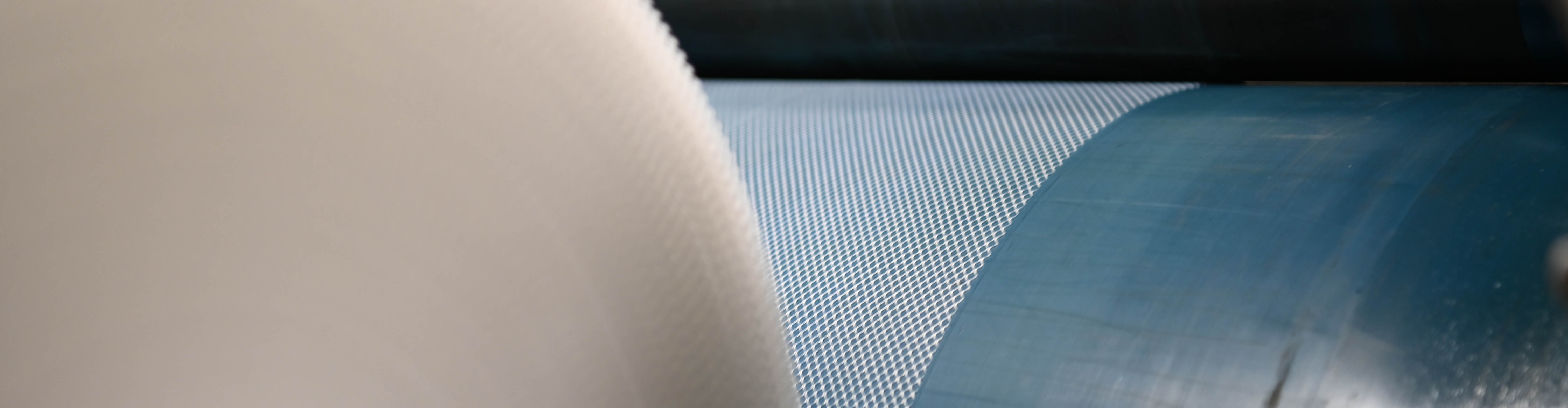

non-halogenated flame retardant resin systems towards tailor-made flame retardant saturations for engine air filter media

Did you know that GESSNER has been the first ones in the market to provide flame-retardant resin systems to protect people? We have patents running and are still pioneering this business.

Flame retardant engine air filter media is not only needed for utility vehicles particularly exposed to ignition sources near welding operations or hot embers. Also, passenger cars are subjected to a non-negligible risk of ignition through glowing embers or sparks, caused for example, by discarded cigarette-butts. The highest share of flame retardants is based on halogen containing compounds. The downside of bromine and chlorine containing flame retardants is, that the increase in safety is at the expense of the environment. Due to their inherent stability, halogenated flame retardants are inclined to accumulate in living organisms, suspected to be harmful to human health or wildlife and can form toxic compounds up on combustion.

Therefore, the demand for non-halogenated flame retardant filter media meeting the regulatory (TSCA and REACH) and environmental as well as the performance challenges is increasing steadily. The development of filter media is shifted from standard manufacturing processes to customized design of resin systems, merging easy processability and fulfilment of flame retardancy standards. A tool box of different fast curing or pre-crosslinked saturations (phenolic, acrylic or epoxy) consisting of phosphorous- and nitrogen-based flame retardant resin systems, allows GESSNER materials to exceed the specifications of the DIN 53438 standard easily. In combination with outstanding physical properties, high efficiency (>99%) and long life time of the filter media a safe and optimum engine performance can be assured.