- Home

- Company Overview

- Applications

- Solutions

- Materials & Technologies

- Trade Shows

- News

- Contact

We specialize in manufacturing high-quality meltblown nonwovens for a wide range of applications - and now also offer a sustainable meltblown nonwoven made from compostable PLA polymer for air filter applications to reduce your carbon footprint. PLA nonwovens offer an eco-friendly yet high-performance alternative filter medium for HVAC and APC applications across various industries.

Our PLA meltblown nonwoven for air filtration is an eco-friendly alternative to conventional synthetic nonwovens. Due to the natural, 100% compostable polymer, the PLA nonwoven offers a reduced product carbon footprint. With reliable performance, mechanical strength and low pressure drop this eco-friendly filter media represents an alternative that can be used in a wide range of air filtration applications meeting ePM1, ePM2.5, ePM10 filter classes.

Our PLA meltblown nonwoven is designed to reduce your product carbon footprint. Engineered from biobased plastics which are 100% industrially compostable, these advanced filter media deliver an impressive average of 85% reduction in carbon footprint compared to traditional polymers when accounting for biogenic carbon content.*

In direct comparison, our PLA meltblown nonwoven fabric has a CO2 footprint that is up to 71% lower than a conventional filter medium made of PP. Thanks to reduced greenhouse gas emissions and lower energy consumption throughout the entire production process, emissions are reduced by over two-thirds and the PCF of our PLA filter medium is reduced to 0,9 kg CO2/ kg including biogenic carbon content. In comparison the same meltblown nonwoven made from PP has a PCF of 3,1 kg CO2/ kg.**

* Plastics Europe data

** Product carbon footprint estimate, cradle-to-gate using primary and secondary data from Sphera MLC 2025.1; Method: IPCC AR6 GWP 100 incl. biogenic carbon

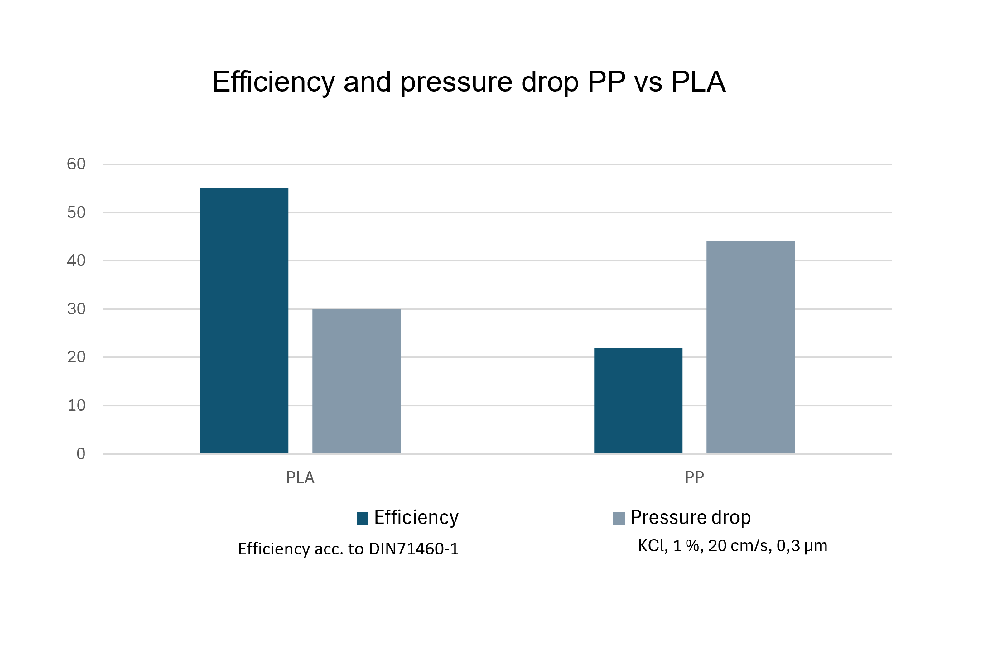

Beyond its environmental advantages, PLA nonwoven demonstrates superior technical performance through enhanced filtration efficiency and lower pressure drop. The polymer structure of PLA offers a longer service life over conventional PP nonwovens, resulting in extended maintenance intervals and improved overall system efficiency. (Grafik Efficiency & pressure drop PP vs. PLA)

Our PLA filter media covers ISO16890 efficiency ratings ePM1, ePM2.5 and ePM10 enables us to cover air filtration performances from standard to high efficiency for a wide range of applications - from HVAC and air pollution control in public, home and industrial settings.

Polylactic Acid (PLA) is a biodegradable and bioactive thermoplastic derived from renewable resources like corn starch, sugarcane, or cassava. The natural origin makes it a non-toxic, eco-friendly alternative to fossil-based plastics.

PLA offers benefits in efficiency, eco-friendliness, and processing. Its thermoplastic properties allow precise fiber structures for high filtration performance and make it easily processable for meltblown nonwoven. As a biodegradable alternative to traditional, petroleum-based plastics, PLA meets environmental regulations and the growing demand for eco-friendly products.

It provides the mechanical strength and flexibility needed for durable filtration under varying conditions. Additionally, PLA integrates seamlessly into existing production processes, enabling manufacturers to adopt sustainable practices without compromising quality or efficiency.

GESSNER produces PLA nonwoven for air filtration applications. Our PLA meltblown nonwoven is suitable for various HVAC and APC filter applications, including:

It delivers high filtration efficiency with a low pressure drop, comparable to or in some cases better than traditional synthetics. Our PLA meltblown nonwoven shows enhanced particle capture efficiency while maintaining a lower airflow resistance than equivalent polypropylene (PP) media.

In practical terms, this means you get excellent air cleaning performance without penalizing energy consumption. The PLA media’s fiber structure also gives it a long service life, so filters can sustain their efficiency longer and require less frequent changes. In short, PLA filter media provides reliable high efficiency and helps reduce pressure-drop related energy costs.

Yes – PLA filter media can be used in high-efficiency air filtration applications. In fact, our PLA meltblown covers ISO 16890 ratings ePM1, ePM2.5, ePM10, which correspond to fine and very fine particle filtration classes. This means it can achieve performance levels from standard HVAC filters up to those capturing extremely fine particles (ePM1 and MERV 13-15 range).

Thanks to its fine fiber structure and chargeability, PLA media can be engineered for demanding uses like advanced HVAC systems, industrial dust collectors, and other high-efficiency filters. It offers an eco-friendly way to reach these efficiency targets without sacrificing performance. For ultra-critical needs such as HEPA filters, PLA technology is still emerging, but it shows promise there as well. It already meets the efficiency classes required for most commercial and industrial high-performance filters.

Under normal operating conditions, PLA filter media is stable and durable. It was developed to have the necessary mechanical strength and flexibility for reliable filtration under varying environmental conditions.

In typical HVAC temperatures and indoor humidity levels, PLA nonwoven maintains its structure and filtration performance for the full service interval. The material doesn’t degrade or lose efficiency in ordinary use (e.g. office or factory ventilation). However, like most polymers, it has its limits: high heat (far above ambient, e.g. consistently >60°C) or prolonged exposure to water may eventually affect it.

In practice, those extremes are outside normal air filtration scenarios. For all standard temperature and humidity ranges encountered in facilities or vehicles, PLA media performs robustly without any special handling. Manufacturers can use it in existing systems confident that it won’t compromise under regular operating conditions.

Substantially – switching to PLA meltblown media can cut a filter product’s carbon footprint by roughly 70%. Our lifecycle analysis shows an up to 71%* lower CO₂ footprint for PLA filter fabric compared to the same filter made with PP.

In numbers, the PLA medium has an estimated Product Carbon Footprint (PCF) of ~0.9 kg CO₂/kg, whereas a conventional PP medium is about 3.1 kg CO₂/kg. This dramatic reduction (over two-thirds less emissions) comes from PLA’s renewable plant-based origins and lower production energy. In addition, using PLA supports sustainability goals – not only does the material itself generate fewer greenhouse gases, but its lower pressure drop can save energy during use, further shrinking the overall carbon impact. For companies aiming to reduce their environmental footprint, PLA filter media is a high-impact solution.

*Product carbon footprint estimate, cradle-to-gate using primary and secondary data from Sphera MLC 2025.1; Method: IPCC AR6 GWP 100 incl. biogenic carbon

Yes. PLA filter media is designed for a sustainable end-of-life, as it is industrially compostable and recyclable.

In an industrial composting facility, the material will biodegrade into water, CO₂, and organic matter under controlled high-temperature conditions. Importantly, no persistent microplastics remain after composting – it fully breaks down into natural compounds.

Alternatively, PLA nonwoven can be recycled: it can be mechanically reprocessed or chemically converted back into lactic monomers to make new plastic. This means used PLA filters can enter recycling streams to “close the loop,” reducing waste. In summary, instead of ending up as permanent waste, a spent PLA filter can be turned into soil nutrients via composting or serve as raw material for new products through recycling.

No – one big advantage of PLA media is that it does not create lasting microplastic pollution.

Being a biodegradable polymer, any fibers or particles of PLA that enter the environment will naturally break down over time. Under composting conditions, it fully disintegrates with no residual microplastics left in the soil. Even in less controlled environments, PLA will fragment and biodegrade much faster than conventional plastics.

This contrasts with petroleum-based fibers (like PP), which can persist as microplastics for decades. So using PLA filter media helps mitigate the microplastics issue: if any small fibers shed or if a used filter is discarded improperly, the material will eventually be metabolized by microorganisms rather than accumulating as pollutant. In essence, PLA is designed to leave behind no long-term plastic fragments, aligning with environmental safety goals.

Our PLA meltblown nonwoven for air filtration is an eco-friendly alternative to conventional synthetic nonwovens. Due to the natural, 100% compostable polymer, the PLA nonwoven offers a reduced product carbon footprint.

At GESSNER, we believe that true innovation arises where performance and sustainability come together. With our cellulose fiber material with eco-friendly lignin saturation, we are addressing precisely this issue - and opening up new perspectives for…

More sustainable fabrics through secondary resources - GESSNER now offers its meltblown nonwoven fabrics for textile applications made from recycled resources.

This cellulose filter media is saturated with an eco-friendly lignin-based resin, ensuring that your filter element offers best performance, while taking a step into more sustainable filtration solutions.

With environmental regulations tightening and consumer demand for eco-friendly practices growing, sustainable packaging is no longer just an ethical choice; it’s a business necessity. The transition from plastic-based packaging to sustainable…

Designed with a strong commitment to reducing carbon footprints and saving of fossil resources, our lignin saturated media is meticulously engineered to provide high-efficiency filtration that meets the highest standards.