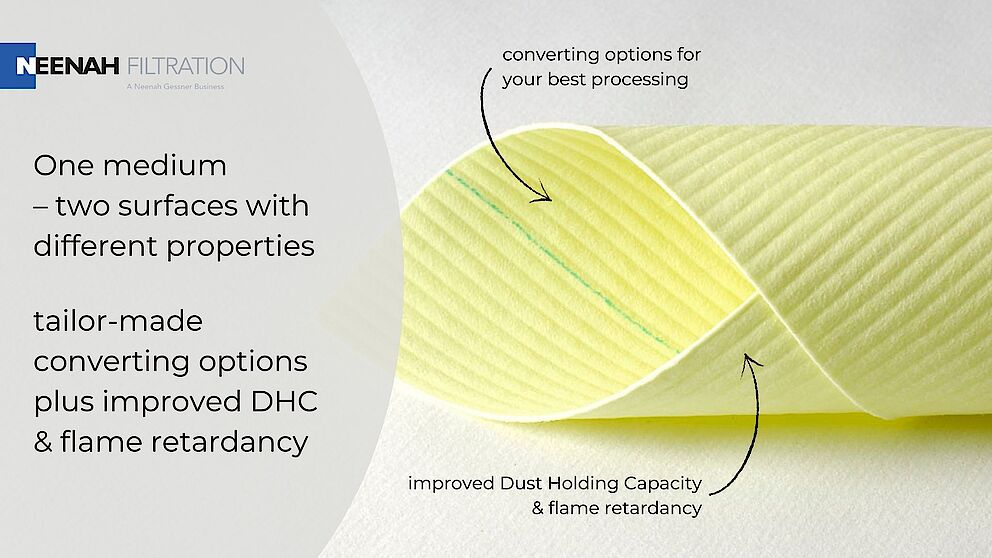

Surfaces with different characteristics – this provides advantages for products & converters in a brand-new way. The asymmetric saturation technology at GESSNER offers physical advantages for filter elements but also processing advantages for converters.

In the engine air application area, it is important that the gradient in the filter medium can be used in the best possible way. This is guaranteed by the choice of binders on the upstream side. For example, on the one hand we can optimize the dust holding capacity (DHC) up to 10%, or even up to 20% in combination with an increasing gradient, while having the function of flame retardancy.

But at the same time, we can also create customer-converting benefits for individual needs through a different resin system on the clean side. These can optional be softness, a non-cured or pre-cured surface or even stiffness - choose able for the individual needs of our customers.

All these possibilities contribute to develop very innovative media for engine air filter elements with a long-life cycle made by one of the best qualities that are available on the market. Additionally, we can ensure the safety aspect for passengers in the cars or trucks, provided by GESSNER™, the pioneer of flame-retardant resin recipes.

Another key function of this “asymmetric saturation” or ability to combine different resin systems on one media is that it allows us to tailor-make our media to meet individual customer needs. Don’t hesitate to contact us for further information. Let GESSNER develop a media that is just right for you!