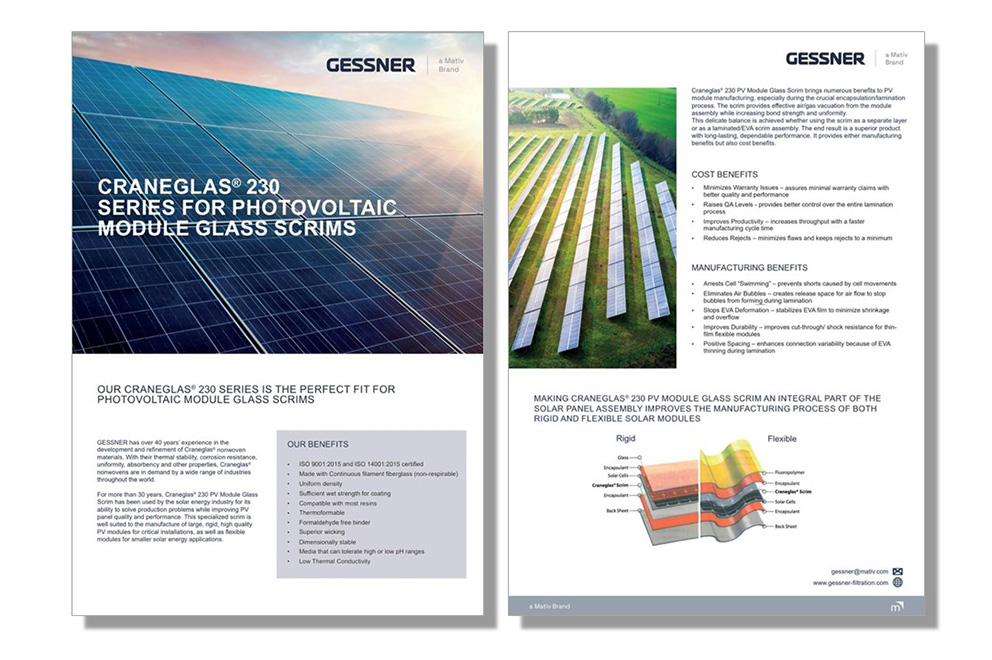

Craneglas™ 230 Series

Enhancing Solar PV Module Lamination with Superior Scrim Solutions

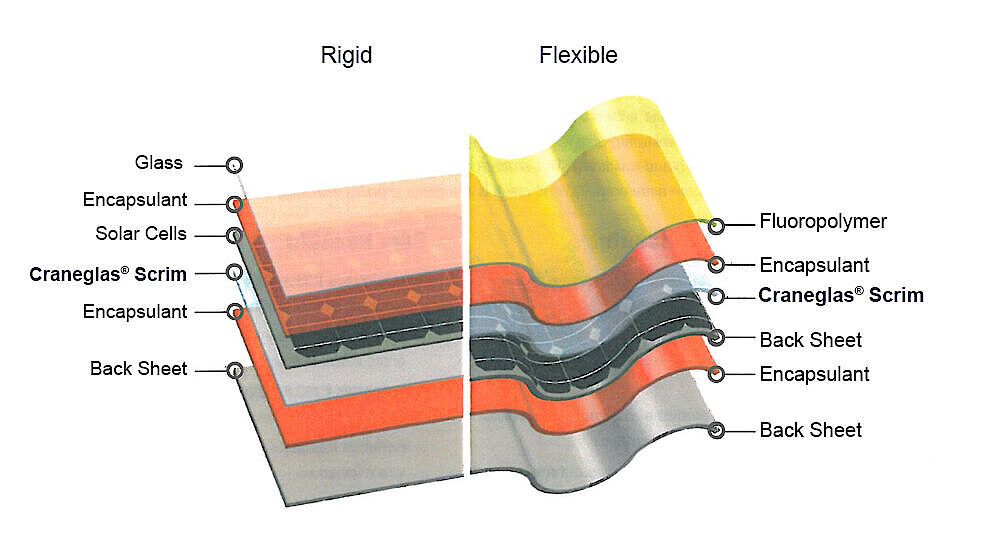

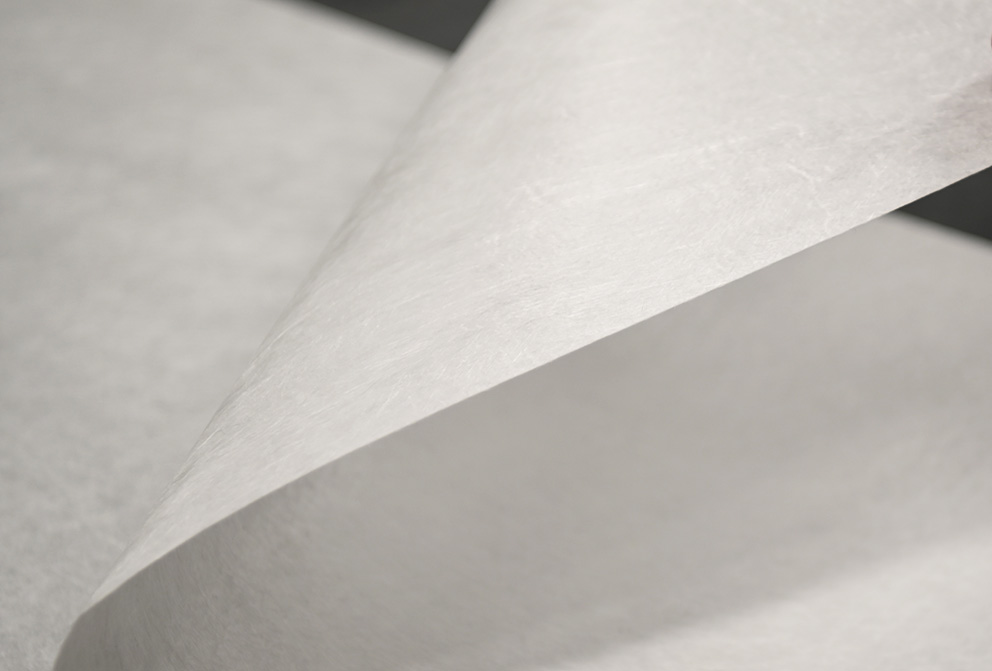

GESSNER's Craneglas™ 230 product series introduces a high-quality, lightweight scrim that has demonstrated exceptional performance and reliability in the lamination of photovoltaic (PV) modules. This innovative material is specifically designed to cater to the needs of large surface area PV modules, ensuring optimal ventilation during the assembly process.

The incorporation of a scrim layer during the lamination process plays a critical role in maintaining the integrity of solar modules. It provides adequate channels for any residual air or other gases that may be trapped during the assembly process. This allows these gases to escape, effectively preventing the formation of bubbles which could potentially lead to the delamination of the modules or even cause module failures once they are installed and operational.

One of the key benefits of our Craneglas™ scrim is its ability to extend the lifespan of the photovoltaic modules. By minimizing the risk of delamination and module failures, it significantly enhances the durability and longevity of the modules, ensuring more efficient and sustainable energy production.

The Craneglas™ scrim features an ideal level of porosity, a critical attribute in the context of PV module lamination. This porosity allows the encapsulation material to flow through smoothly, facilitating the creation of a robust bond between the cell and the backsheet. Simultaneously, it enables the trapped gases to escape through the air channels formed by the scrim.

In conclusion, GESSNER's Craneglas™ 230 series is redefining the standards for solar PV module lamination. Leveraging the power of a superior scrim solution, we're enabling enhanced module performance, longevity, and overall efficiency in solar energy production.