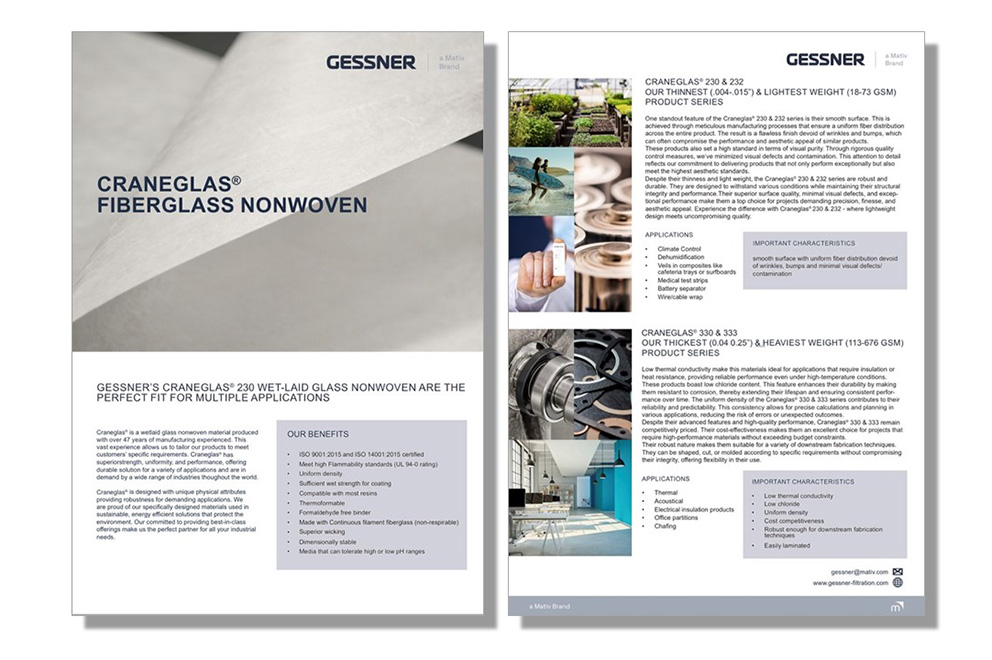

Craneglas™ 333

A Versatile, High-Performance Medium for Insulation Applications Amidst Market Challenges

GESSNER introduces Craneglas™ 333, a medium specifically designed for thermal, electrical, and acoustic insulation applications, thereby offering our customers a fair and accessible option in these challenging market conditions.

The Craneglas™ 333 product line is uniquely suited for appliance gasket applications due to its ideal thermal conductivity, density, and durability. Despite these high-performance characteristics, we've managed to maintain competitive pricing, ensuring excellent value for our customers.

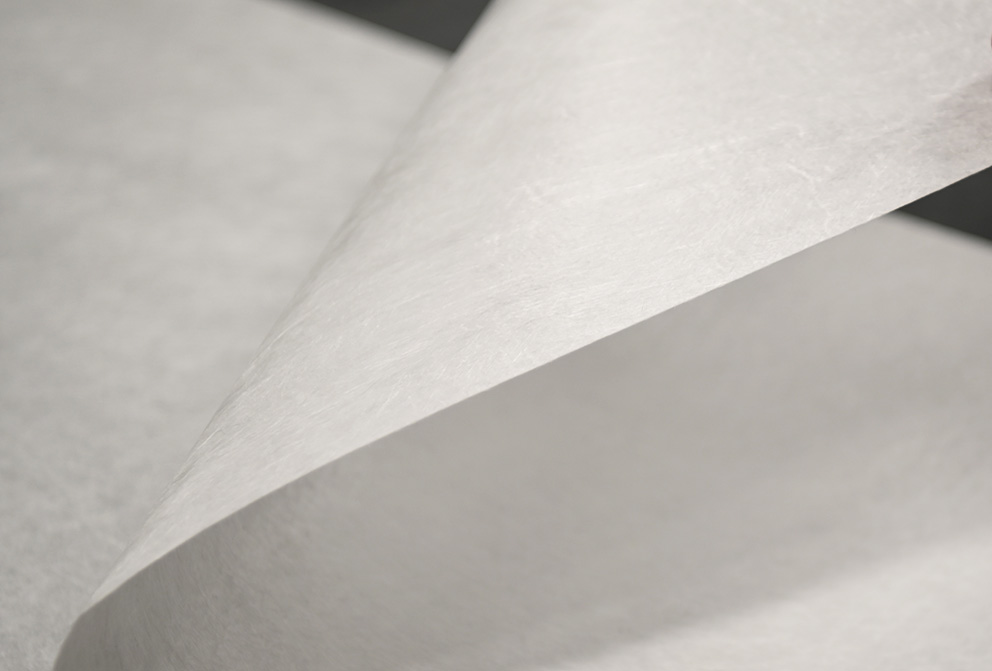

One distinctive feature of the Craneglas™ 333 series is the slightly larger fiber diameter, resulting in an open-pore structure. This unique structure is ideal for lamination with universal adhesives and binders, enhancing its versatility in various applications.

Further adding to its adaptability, Craneglas™ 333 can be easily die-cut into specific shapes as per the requirements of the customer's individual application. This ensures that the final product aligns perfectly with the customer's specifications, delivering a customized solution that meets their unique needs.

At GESSNER, we understand that not all projects require large quantities of material. That's why we've optimized our production processes to cater to smaller orders. Our machines are capable of supplying small batch sizes to meet production requirements of 3,000 lbs. and above, ensuring that we can accommodate the needs of all our customers.

In summary, GESSNER's Craneglas™ 333 series provides a robust and adaptable solution for appliance gasket applications. Amidst the current market challenges, we're committed to delivering high-quality, customizable, and cost-effective products that meet our customers' diverse needs.