Fully Sustainable Sacket Packaging

Our coated material consists of 100% certified cellulose fibers which make it a fully sustainable packaging solution. Even though the BMUV's current Packaging Act still allows 5% of the components of packaging not to be fully compostable, we abstain from all non-biological components. The coating of our packaging materials is free of all petrochemical components and is therefore 100% ecological and SUPD (Single Use Plastic Directive) conform.

Our fiber-based, coated material is a very lightweight packaging solution with only 70 gsm grammage, ideal for reducing material waste without compromising durability.

The sustainable nature of our packaging solution comes with full recyclability and biodegradability, which can be certified by PTS. This enables easy disposal of the packaging in the paper waste stream.

Seal the Deal on Sustainability

A single-sided coating provides the possibility of printability, with a coating weight of up to 15g/m². With its heat seal properties (A-A sealable - coated to coated side) our material can be processed without additional adhesive or other aids. The elongation in MD is more than 6% and enables therefore perfect processing on printing and flowpack machines. A two-layer coating is also available to increase heat sealability in your converting process.

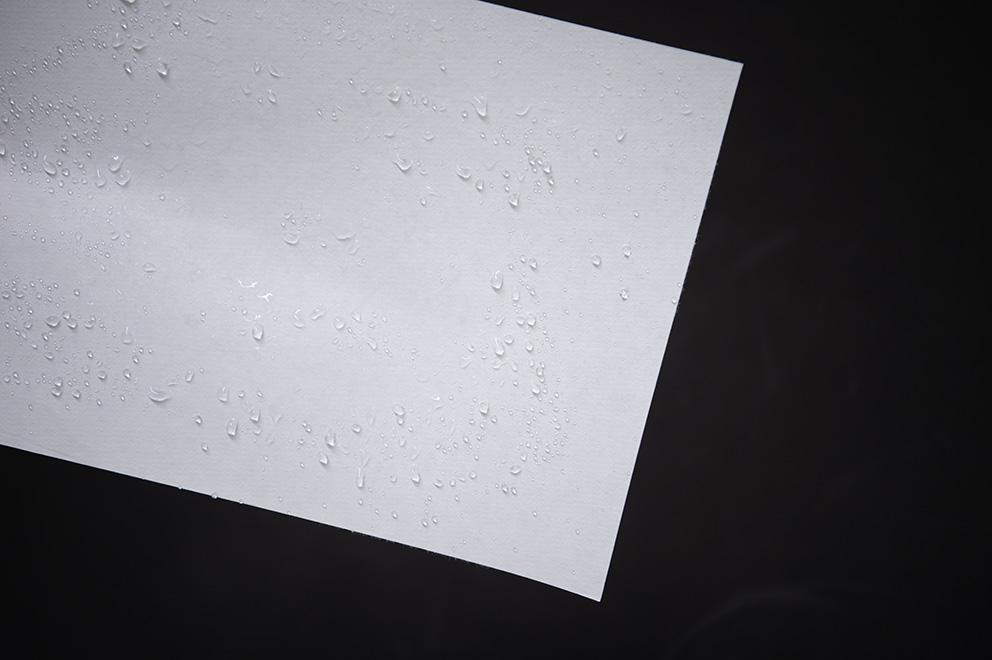

With the option of an MVTR impregnation (Moisture Vapor Transmission Rate) we are able to offer additional protection for the packed goods. The MVTR acts as a robust barrier to keep content fresh by controlling the amount of moisture that passes through the packaging. This helps prevent spoilage, maintain product quality, and extend shelf life, making it ideal for items sensitive to humidity or moisture.

From Best-In-Class Functionality to Food Safety

Fully certified by ISEGA, our sustainable packaging meets stringent safety and environmental standards, ensuring it’s safe for food-grade applications.

When developing our coated packaging paper, we made sure that it can be optimally processed on packaging machines and printed on a wide range of printers. Where the application requires special surface properties, our material is also available with a natural-based pre-impregnation to improve the softness of the paper.

In addition, previous processing of the paper has shown an extremely low dust tendency. Printing machines sometimes must be cleaned frequently during printing due to heavy dust accumulation - with our material, the machine can be operated up to 5 times longer than with market competitors.