GESSNER™ FOR HIGH EFFICIENT FUEL FILTRATION

DISCOVER THE POWER OF EFFICIENT FILTRATION WITH OUR ENHANCED GLASS MEDIA

Our innovative glass containing filter media reaches highest possible efficiencies and still retaines DHC - while a glass fiber shedding is avoided with a special technology.

Revolutionizing the Trucking Industry: Advancements in Engine Protection Technology

The world of trucking is seeing a seismic shift with the advent of cutting-edge engine protection technologies. As trucks traverse hundreds of kilometers daily, carrying diverse goods, their reliability becomes paramount. This reliability stems from the robustness of the engine, which is often subjected to extreme environmental conditions.

Today's modern trucks operate at high injection pressures and often encounter particulate contaminants in fuel. These factors necessitate the use of a durable and highly efficient filter element for safeguarding the diesel engine. A top-tier fuel filter element boasts an efficiency of up to 99.95% (for particles larger than 4µm), ensuring the engine's longevity by preventing microscopic debris from causing wear or damage.

In addition to this, advances in lubricant technology further enhance engine protection. New generation lubricants offer increased wear protection, oxidation control, and extended oil life. This not only protects the engine but also reduces maintenance and fuel costs, thereby proving economical in the long run.

Furthermore, idling reduction technologies (IRTs) have emerged as a game-changer. These devices allow engine operators to minimize long-duration idling of the main propulsion engine, thereby reducing unnecessary fuel consumption and emissions.

As we move forward in 2023, these technological advancements in engine protection are not just improving the performance and lifespan of truck engines, but also contributing to a greener and more sustainable future for the trucking industry.

Filtering the Future: GESSNER’s 3-layer Design for Peak Performance

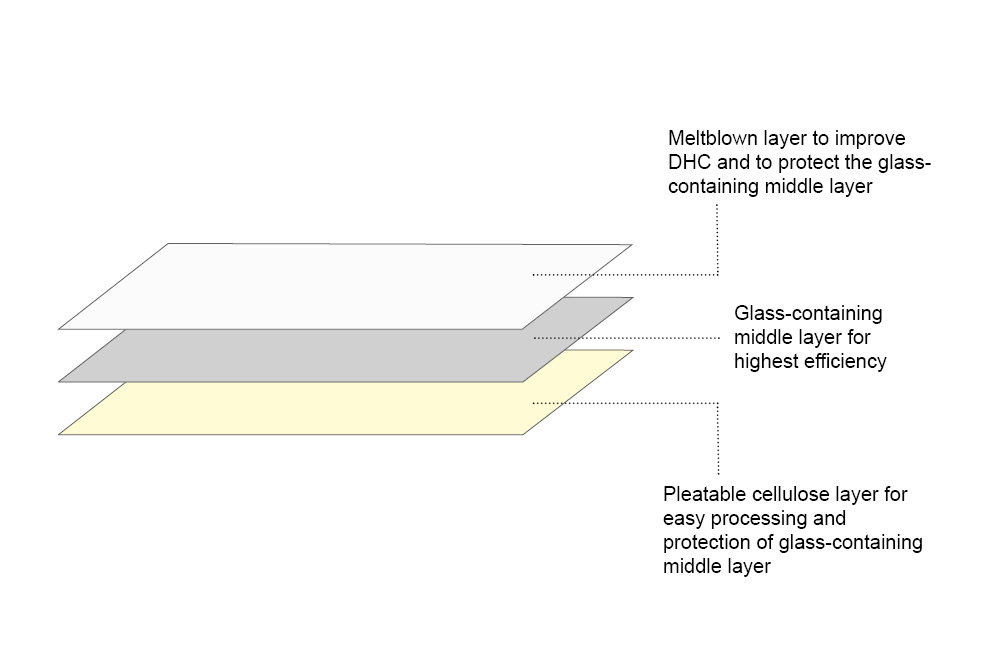

GESSNER is taking the lead in fuel filter media technology with its distinctive 3-layer design. The high efficiencies and dust holding capacities are achieved through this unique structure, exclusively crafted in Germany.

The middle layer of the filter media houses micro-glass, ensuring the highest efficiency levels. To prevent any loss of glass fibers, this layer is ingeniously sandwiched between a meltblown layer and a cellulose layer. The meltblown layer serves a dual role: it enhances the Dust Holding Capacity (DHC) and offers protection to the micro-glass layer from above. Simultaneously, the saturated cellulose layer ensures good foldability, making it possible for our GESSNER™ material to be processed on standard equipment.

Despite the addition of the glass medium, there is no difference in application compared to a traditional meltblown-cellulose combination. This innovative material design was developed in direct response to our customers' concerns about health risks, processability, and the abrasion behavior of glass fibers. The sandwich structure effectively prevents fiberglass detachment, safeguarding your employees while delivering maximum performance to your customers in the application.