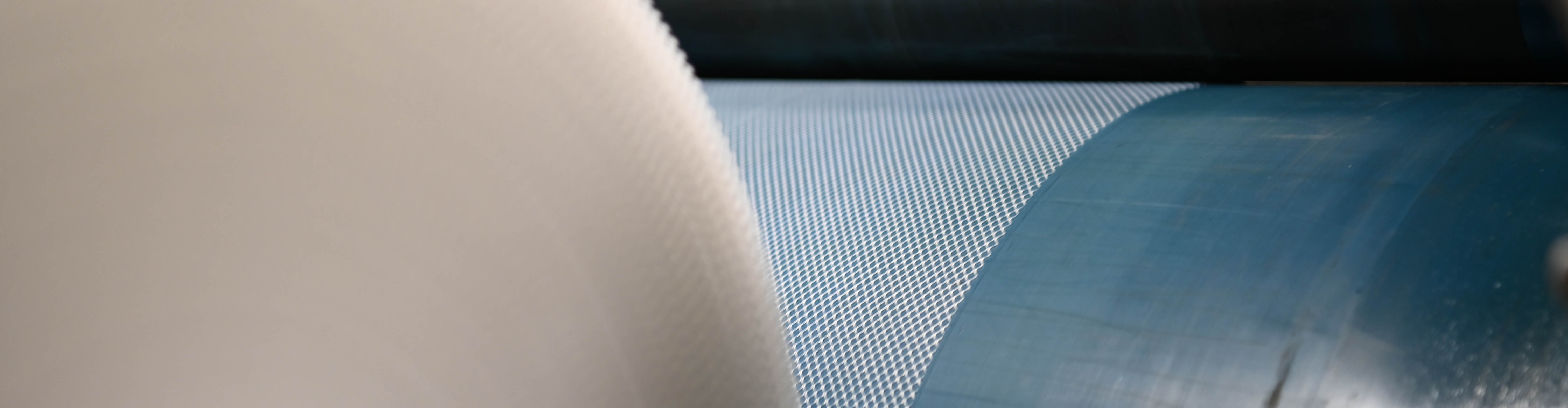

NALTEX™ SLEEVES

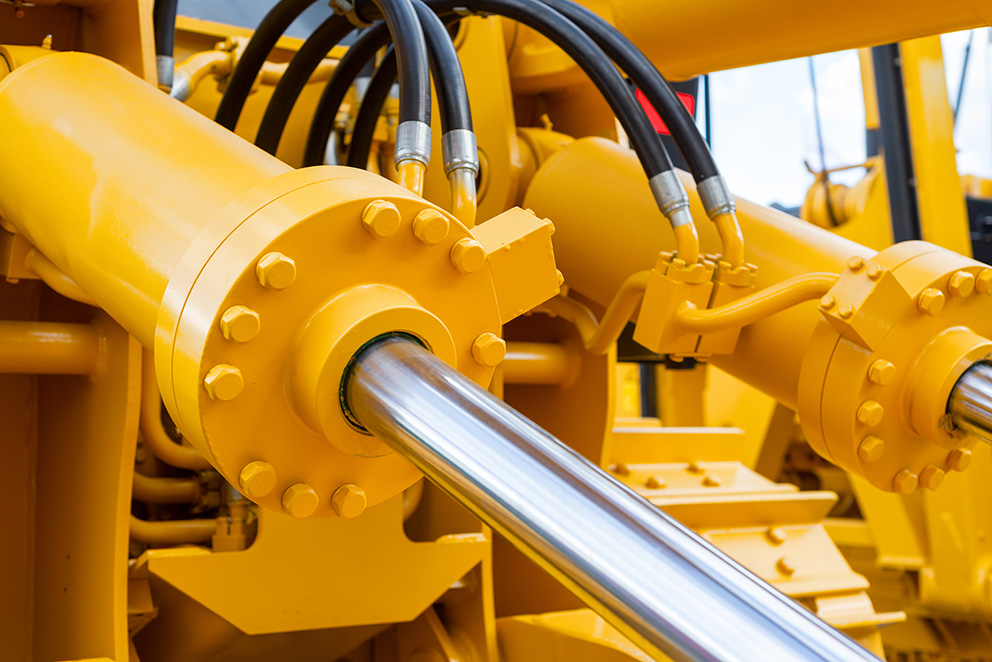

Naltex™ Extruded Sleeves are meticulously designed for Parts Protection, offering an array of stretch and recovery properties to safeguard straight shafts or cylinders. These sleeves are tailored to your needs, available both in specific cut lengths and in a selection of five distinctive styles, each offering varying degrees of protection. Naltex™ Extruded Sleeves deliver unmatched durability and protection, ensuring your parts remain in pristine condition.

We prioritize quality and durability in all our products. Our machined parts are not only rust-proof but also designed with an extruded solution that resists damage caused by corrosion. This ensures the longevity of our parts and helps you avoid frequent replacements. Moreover, our products are incinerable, a feature that significantly reduces costs associated with the disposal of traditional wire support. This cost-effective option promotes sustainability while delivering top-notch performance. We understand that every operation has unique needs. That's why we offer a variety of resins that are compatible with aggressive chemicals and high temperatures. Whether your environment is harsh or gentle, our parts are designed to withstand the conditions. Our cages are available in a wide range of sizes, from ¼”- 24” and 6.3 - 610mm in diameter, and come in a variety of colors. This breadth of options allows you to choose the best fit for your specific needs. Our resins can be modified to meet any product and stretch profile, ensuring that you get a product tailored to your exact specifications.