GESSNER'S SATURATION TECHNOLOGY

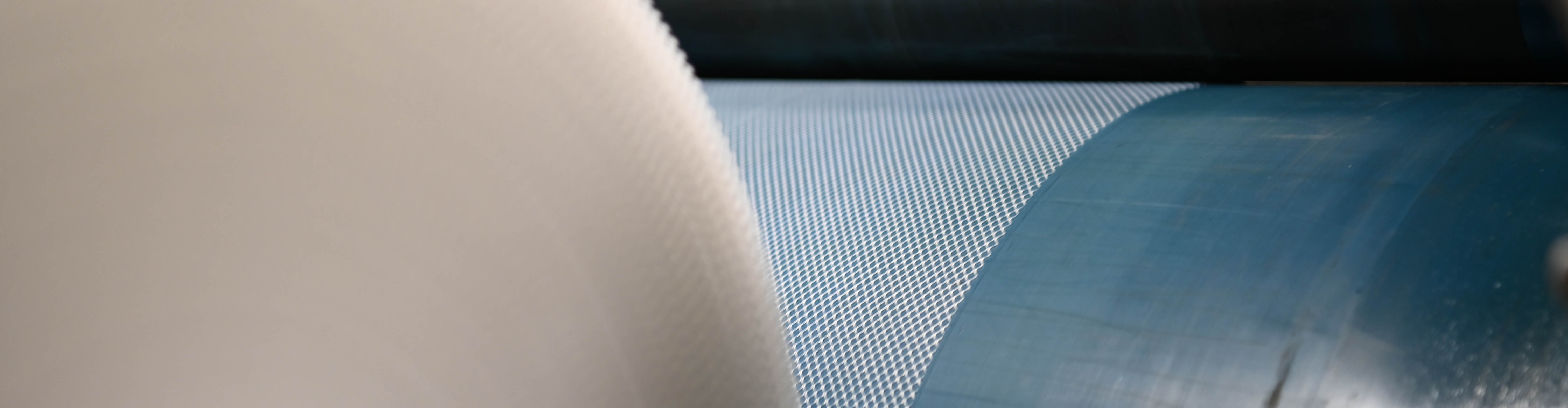

GESSNER impregnates its special technical papers using a process based on methanol or water. Impregnating with phenolic, epoxy, acrylic resins or latex gives high strength, dimensional stability and improves resistance to solvents, chemicals and high temperatures.

Special additives, depending on need, can be added to give further functionality. For example, hydrophobic, hydrophilic or oleophobic properties, flame retardancy, various colors, UV stability, bactericides, fungicides, etc, can all be built-in. Using further coating devices, we can add still further functionalities.

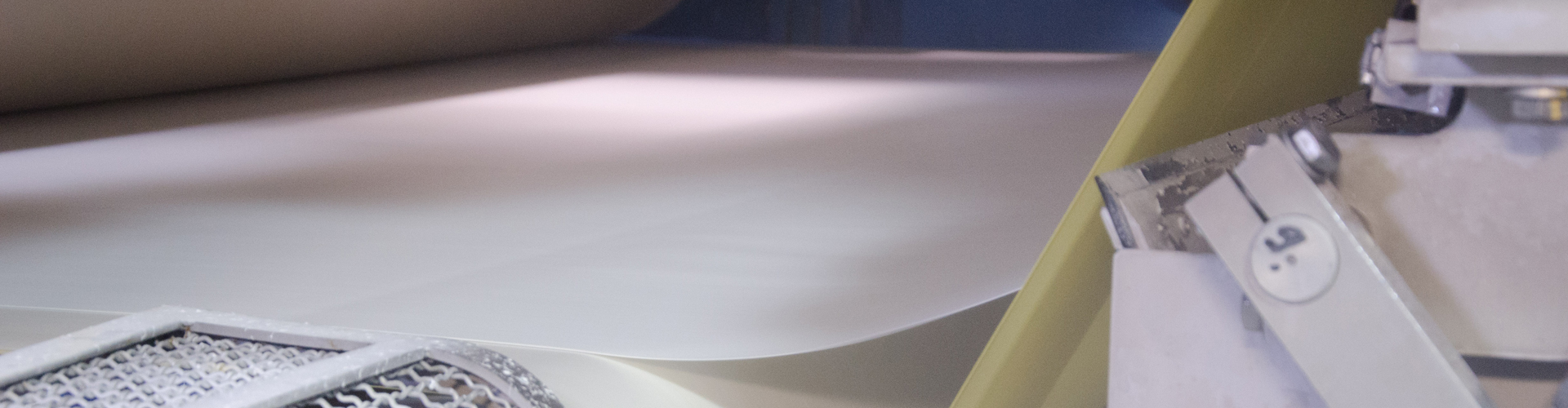

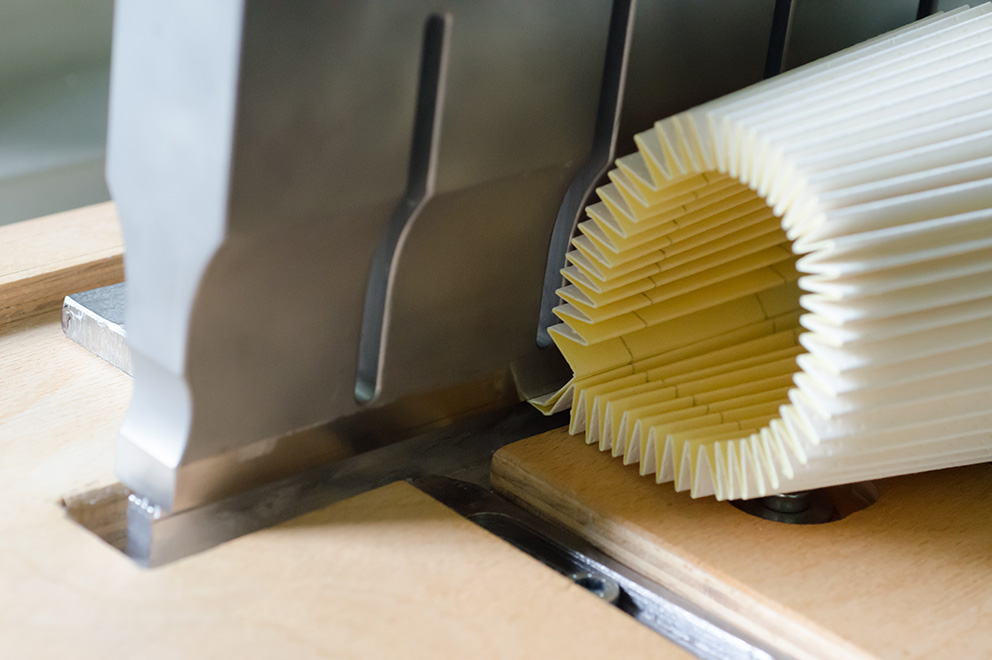

GESSNER's ability of an asymmetric saturation process provides many different functionalities of cellulose-based media. Utilising an asymmetric saturation process is essential for ensuring that impregnation filter media can provide optimal filtration capabilities when used in a range of industrial settings, especially when it comes to customized and very special requirements. GESSNER mentions below only a few examples of what is possible by using this special process.

- benefits of curing and non-curing resins in one single medium for filter manufacturers. Our two-sided media provides different characteristics which unlocks advantages for our products & converters in a brand-new way

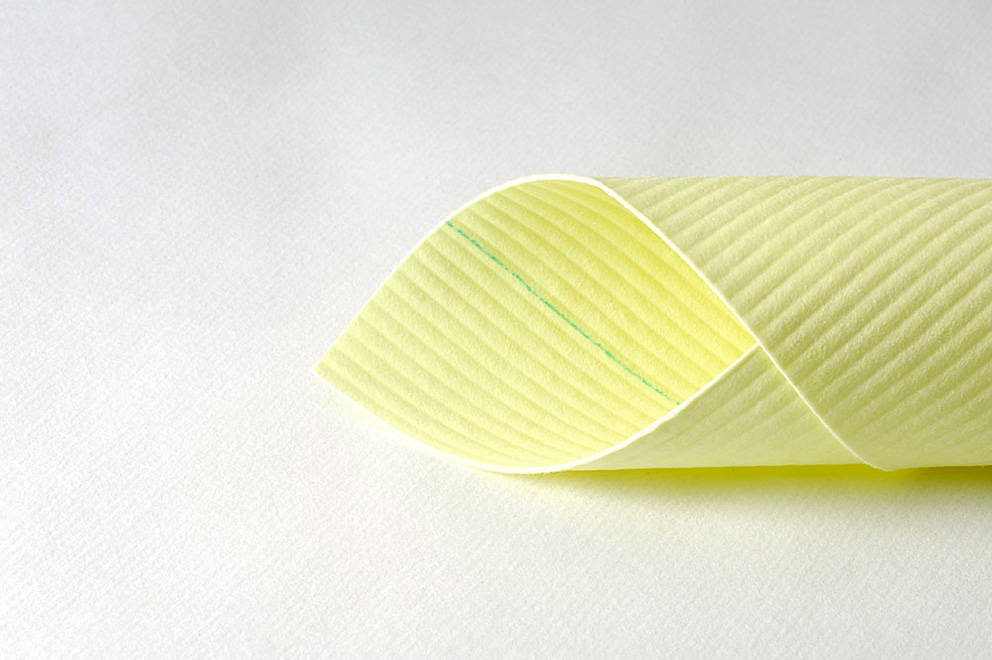

LEARN MORE - superior converting for filter manufacturer of paper-processing industries to combine paper by an ultrasonic welding process on the paper-side without any additional glues or adhesives

LEARN MORE - physical advantages for filter elements but also processing advantages for converters, e.g. One medium – two surfaces with different properties: Improved dust holding capacity and flame retardancy while offering you tailor-made converting advantages

LEARN MORE